ROI of Hangar Stacking Software: Real Numbers That Matter

Published on May 5, 2025 • 5 min read

A typical 40,000 square foot hangar can potentially increase monthly revenue by $100,000 through automated stacking optimization. While exact ROI varies based on current utilization and pricing, the financial impact merits serious consideration.

The mathematics support this potential: Because in an industry where hangar space is at 100% occupancy in major markets and new construction costs $300-433 per square foot, the only path to growth is optimization.

The Hidden Cost of Manual Stacking

Most FBOs are leaving serious money on the table. Industry data shows manual hangar operations typically achieve 68-75% space utilization, while optimized facilities can reach 85-90%. For a 40,000 square foot facility charging $1.50 per square foot monthly, improving from 70% to 85% utilization represents $18,000 in additional monthly revenue—or $216,000 annually. Understanding best practices for hangar optimization is the first step toward capturing this revenue.

But inefficiency is just the start. Consider these hidden costs: Hangar rash incidents cost the industry tens of millions annually. One damaged G650 winglet can run $500,000 in repairs plus weeks of lost customer revenue. FBOs report spending 3-5 hours daily on manual stacking calculations and repositioning—that's $50,000+ in annual labor costs for tasks software handles in seconds.

Modern jets like the G650 require 10,000+ sq ft—making efficient stacking critical

Modern jets like the G650 require 10,000+ sq ft—making efficient stacking critical

Real-World ROI: Running the Numbers

Let's model a typical scenario using actual industry data:

Your Hangar:

- 40,000 square feet total space

- Current utilization: 110% (slight overbooking)

- Tenant rate: $1.50/sq ft/month

- Transient rate: $0.15/sq ft/day

With Automated Stacking:

- 5% utilization increase from better layouts

- Room for 2 additional small planes (Citation CJ3)

- Room for 1 additional medium jet (Challenger 350)

- Zero additional large jets (space maxed)

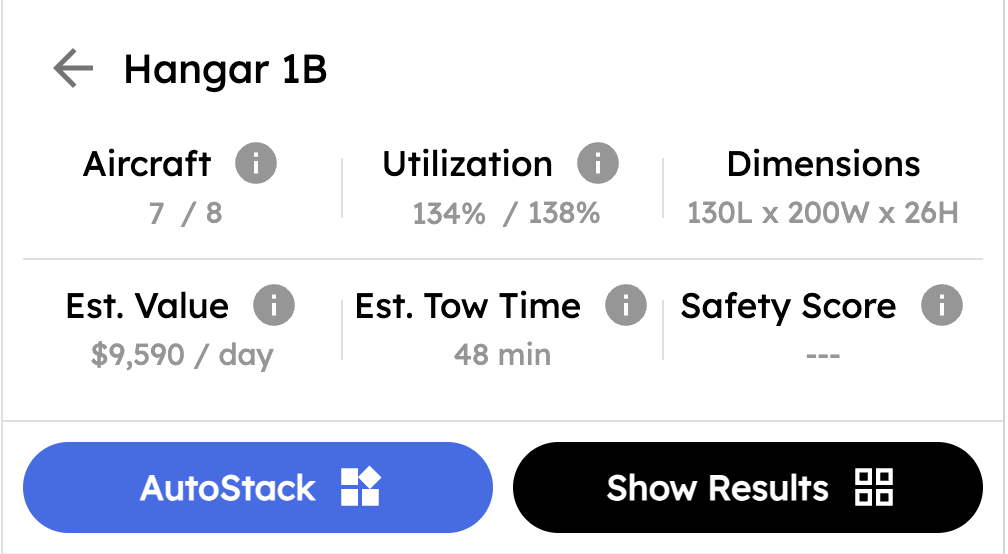

The results? Direct hangar revenue increases by $5,446 monthly. Most analyses overlook fuel revenue. According to NATA data, each dollar of hangar revenue typically generates $2.50 in fuel sales. Total monthly value created: $19,061.

At $450 per month for enterprise hangar optimization software, that's substantial ROI potential. However, these numbers assume optimal conditions and immediate implementation success. More realistic expectations show 25-40% revenue increases within the first year, as reported by industry sources implementing strategic hangar optimization.

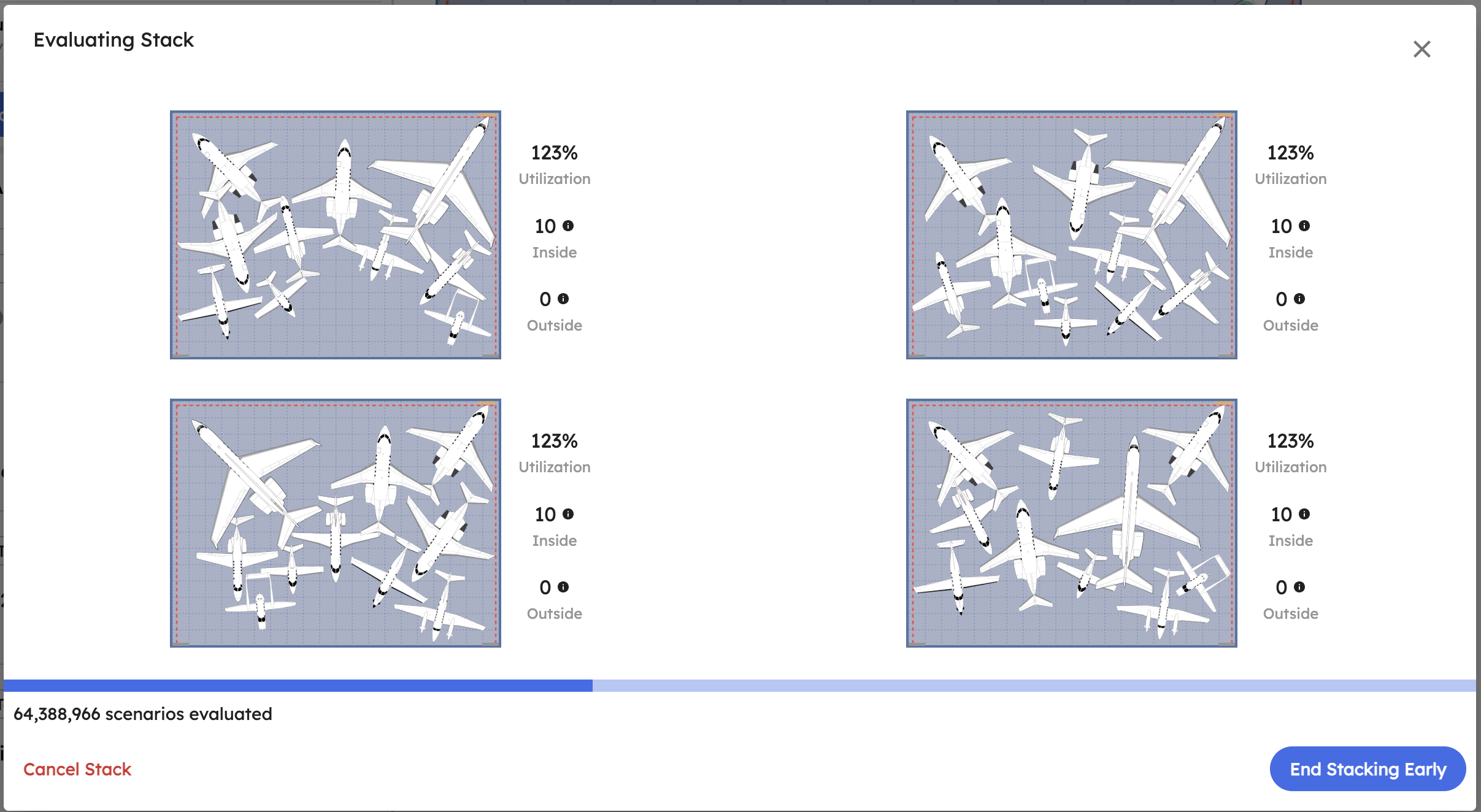

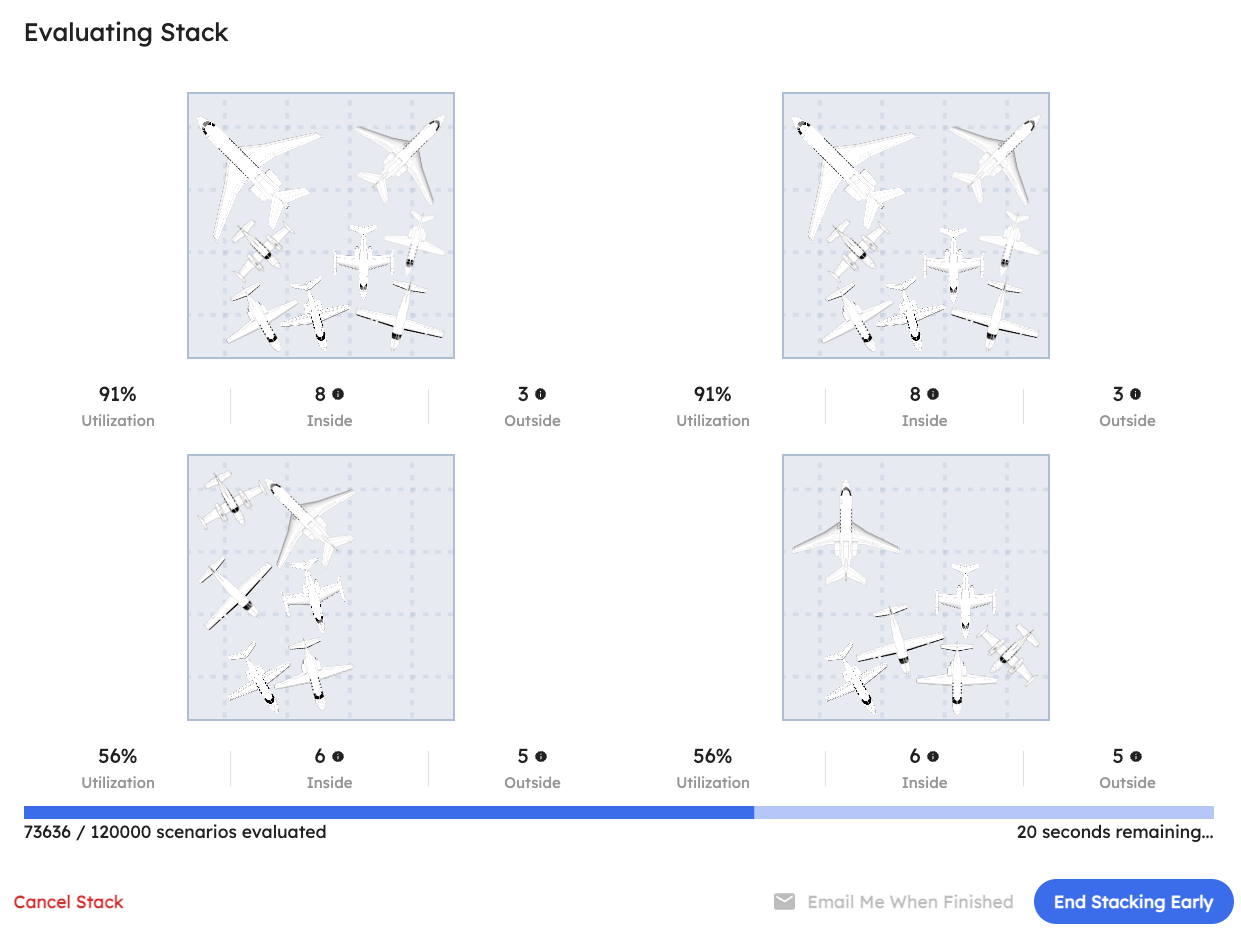

Real-time optimization dashboards transform data into revenue opportunities

Beyond the Numbers: Strategic Advantages

The financial ROI tells only part of the story. Forward-thinking FBOs are discovering strategic benefits that compound over time:

Win More Business: When a G650 operator calls needing space tonight, you know instantly if you can accommodate them without the delay that sends them to competitors. Software shows exact placement options in seconds, including 3D overlap possibilities you'd never spot manually.

Reduce Risk Exposure: One major hangar rash incident can wipe out a year's profit. Automated systems provide clear tow paths, maintain required clearances, and create accountability with digital movement records. Insurance carriers are starting to offer premium discounts for facilities using verified stacking software.

Scale Your Operations: The labor shortage isn't ending. Finding experienced hangar supervisors who can mentally calculate complex 3D stacking arrangements is nearly impossible. Software democratizes this expertise, though new staff still need proper training on aircraft handling, safety protocols, and your specific operational procedures.

Understanding Efficiency Gains

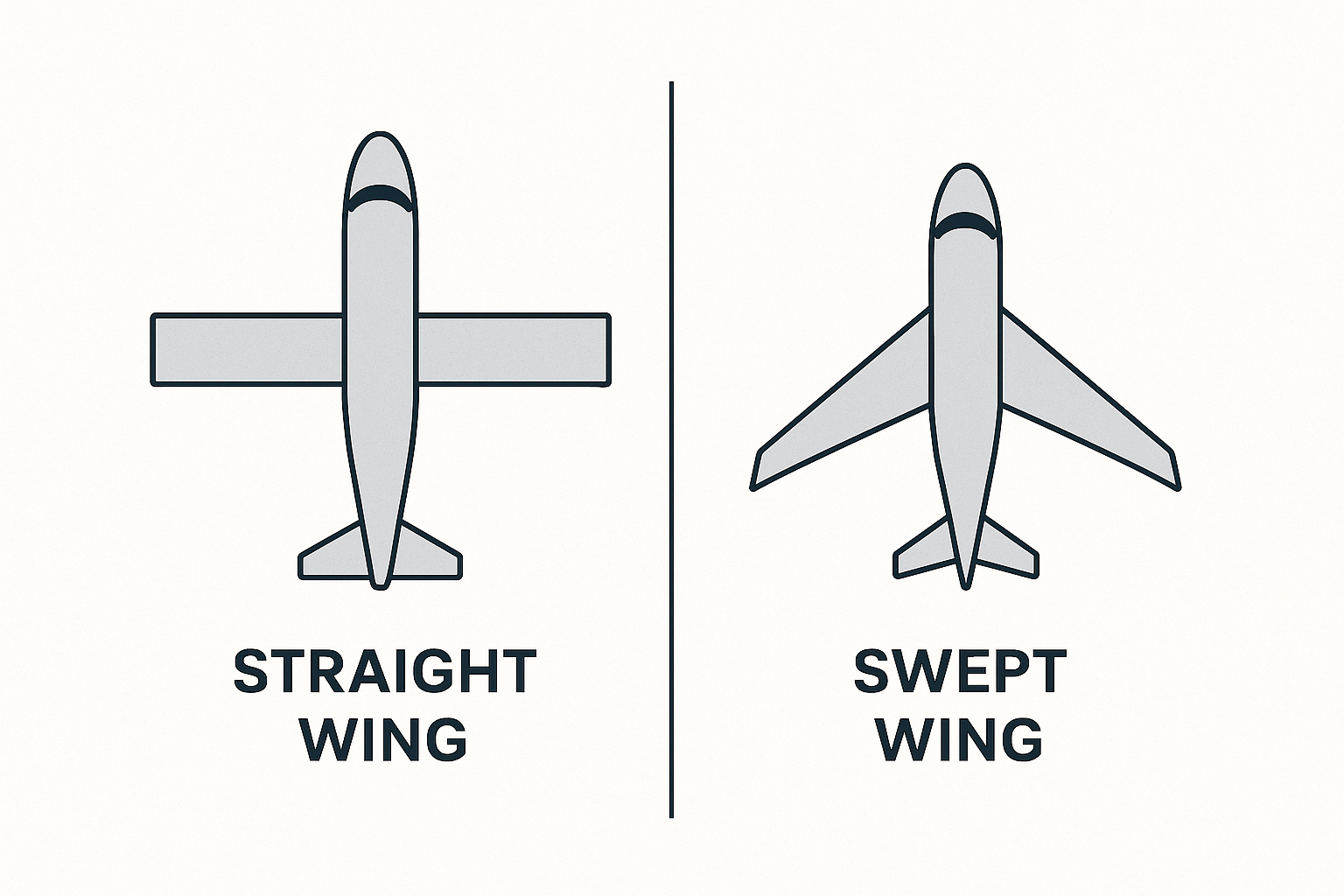

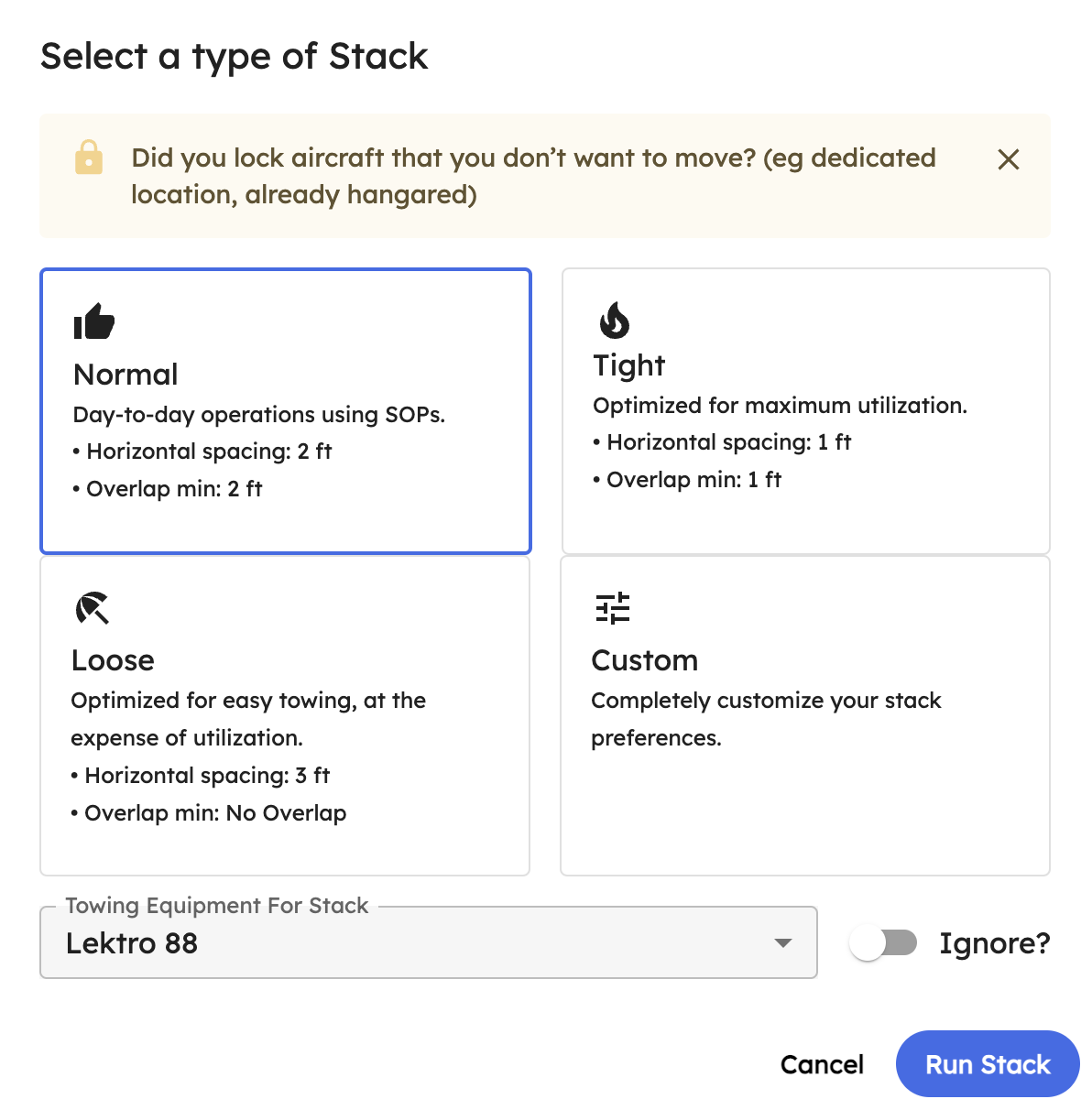

Multiple vendors report their software increases space efficiency by 10-15%. This may be conservative because: Traditional stacking relies on 2D floor plans and institutional knowledge. Automated systems consider true 3D space, accounting for tail heights, wing overlaps, and nose-to-tail configurations impossible to visualize manually.

Case study: A Southeast regional airport's FBO thought their 60,000 square foot hangar was maxed at 18 aircraft. Optimization software identified configurations supporting 22 aircraft—a 22% capacity increase without adding a single square foot. At $2/sq ft rates, that's $192,000 in annual revenue discovered by algorithm. Learn more about 3D aircraft stacking strategies that enable these capacity gains.

3D stacking algorithms see opportunities humans miss

Implementation Realities

While the financial case for hangar optimization is compelling, experienced FBO operators understand that technology implementation requires careful planning. Expect these challenges:

Integration Complexity: Most FBO management systems weren't designed for real-time hangar optimization. Data sync issues, duplicate entries, and workflow disruptions are common during the first few months. Budget extra time for IT support.

Staff Resistance: Your hangar supervisors have years of experience positioning aircraft. Some may resist software recommendations, especially when algorithms suggest configurations they wouldn't choose manually. Change management is crucial.

System Limitations: No software handles every edge case. Unusual aircraft configurations, maintenance requirements, or customer-specific positioning requests still require human judgment. The system supports decisions but doesn't replace operational expertise. Some aircraft present unique hangar optimization challenges that require special attention.

Backup Plans: What happens when the system is down? You need manual procedures and staff who can still calculate stacking arrangements the old-fashioned way. Technology should enhance, not replace, fundamental operational capabilities.

Implementation Timeline

Implementation timelines vary, but most FBOs see meaningful results within 2-4 weeks. Modern hangar optimization platforms offer:

- Pre-loaded database of 600+ aircraft specifications

- Drag-and-drop interface requiring minimal technical expertise

- Cloud-based access from any device (desktop, tablet, phone)

- Integration capabilities with existing FBO management systems

- Real-time synchronization across your team

Implementation Realities:

- Staff training typically requires 1-2 weeks for full proficiency

- System integration may take additional time depending on existing infrastructure

- Change management is crucial—your team needs to adapt workflows

- Initial optimization may reveal operational processes that need adjustment

While vendors promise quick deployment, meaningful operational change requires time. Budget for proper training and process adaptation to realize full benefits.

Verifying Your ROI: A Reality Check

Before committing to hangar optimization software, smart FBO operators should verify vendor claims with actual users. Here's your due diligence checklist:

Reference Calls: Ask vendors for contacts at similar-sized FBOs who've used their software for 12+ months. Ask specific questions about actual utilization improvements, implementation challenges, and ongoing support needs.

Pilot Programs: Many vendors offer trial periods or pilot implementations. Use these to test the software with your actual aircraft mix and operational constraints before committing to annual contracts.

Baseline Measurements: Document your current utilization rates, average aircraft positioning time, and revenue per square foot before implementation. Without solid baseline data, you can't measure actual improvement.

Phased Implementation: Consider starting with one hangar before rolling out facility-wide. This allows you to identify operational issues and train staff without disrupting your entire operation.

Contract Terms: Pay attention to data ownership, cancellation terms, and ongoing support costs. Some vendors charge extra for integrations, training, or customer support that should be included in base pricing.

Summary

With new hangar construction costing $9-13 million for 30,000 square feet, hangar stacking software represents a compelling alternative to expansion. While the exact ROI depends on your current utilization, pricing, and operational efficiency, the potential for 25-40% revenue increases makes this technology worth serious evaluation.

In major markets where hangars are 100% full and waitlists stretch for years, every square foot counts. The question isn't whether optimization software is a magic bullet—it's whether you can afford to ignore a tool that could unlock significant untapped revenue in your existing facilities.

While you're turning away that transient G650 tonight, the FBO across the field accommodates them using optimization software. That's $1,500 in overnight fees, 10,000 gallons of Jet-A, and a new client relationship secured through better space management. Understanding aviation industry trends helps FBOs stay competitive in this evolving landscape.

Calculate Your ROI

Use the AirPlx ROI Calculator to model your exact hangar configuration and discover your revenue potential. Most FBOs discover significant untapped revenue opportunities.