Weird Hangar Shapes and the Ground Damage They Cause

Published on January 6, 2026 • 5 min read

According to IBAC data, 71% of aircraft damage comes from collisions with ground equipment, other aircraft, or static objects like columns and hangar walls. That's not a typo—nearly three-quarters of all damage happens on the ground, not in the air.

Those odds get worse when your hangar wasn't designed for aircraft in the first place.

When Buildings Weren't Built for Planes

At Poplar Grove Airport in Illinois, Dick Thomas transformed his family farm into an airport in 1972. His first hangars were the existing cattle sheds. Today, Poplar Grove has grown into an airpark community with proper hangars featuring 60-foot widths and 18-foot heights—but plenty of FBOs across the country still operate out of converted structures.

The Tillamook Air Museum in Oregon sits inside Hangar B, one of the largest clear-span wooden structures in the world. Built in 1942 to house Navy K-class airships, it's 1,072 feet long and 296 feet wide. During WWII steel rationing, the Navy built it entirely from wood—over two million board feet of Oregon lumber. Its twin, Hangar A, burned down in 1992.

Then there are the Tustin Blimp Hangars in California—17 stories high and built almost entirely of wood. Each could hold six blimps. These structures are engineering marvels, but they weren't designed for the wingspan clearances and floor loads of modern business jets.

Modern aircraft in a clear-span hangar—no columns to navigate around

Modern aircraft in a clear-span hangar—no columns to navigate around

The Column Problem

Modern hangars use "clear span" construction—no internal support columns. But visit any airport built before 1990 and you'll find hangars with columns placed like an obstacle course.

One pilot on an aviation forum described their experience: "Everything in my hangar has wheels. Not because I like mobility, but because I need to play Tetris every time someone wants their plane out."

Another mentioned needing wing walkers at all four corners just to navigate between columns—turning a simple repositioning into a six-person operation.

The numbers back this up. According to six years of IBAC ground damage data:

- 26% of incidents involve aircraft hitting ground service equipment

- 25% happen during towing and pushback operations

- 15% involve aircraft hitting immovable objects (columns, walls, door frames)

- 10% are aircraft-to-aircraft contact

Jason Mann from Western Jet Aviation puts it bluntly: about 50% of ground damage comes from inattention, and the other 50% from rushing or cutting corners. The repair costs? Composite damage alone runs $50,000 to $100,000, with major repairs taking up to six months.

Support columns: great for structural integrity, challenging for aircraft movement

Support columns: great for structural integrity, challenging for aircraft movement

Quonset Huts and Curved Walls

Quonset huts—those semi-circular corrugated steel structures from WWII—are 100% clear span. No columns. But the curved walls create dead zones along the edges that eat into your usable space.

As one FBO manager described: "It's like parking in a giant tin can. The center's great, but good luck using those last 10 feet on either side."

For clear span requirements by aircraft type:

- Single-engine aircraft: 40-60 feet

- Twin-engine aircraft: 60-80 feet

- Corporate jets: 80-120 feet

- Multiple aircraft: 150+ feet

When your building's usable width doesn't match these requirements, every aircraft movement becomes a puzzle.

What Actually Helps

You can't relocate a concrete column. But you can work around it.

Know your clearances cold. Measure every column, beam, and door frame to the inch. Create a clearance chart for your most common aircraft types—wingspan, tail height, and turning radius for each. Post it where your line crew can reference it. The difference between "it should fit" and "it fits with 4 inches to spare" is the difference between a clean record and an insurance claim.

Standardize movement protocols. NBAA recommends coordinated briefings between flight and ground crews, wing walkers during aircraft movement, and written SOPs for both line crews and pilots. For hangars with obstacles, this means designating specific approach paths, requiring two-person verification for tight moves, and never rushing a repositioning because a customer is waiting. The 11% of incidents caused by towing are almost entirely preventable with proper protocols.

Use the right equipment. Towbar-less tugs eliminate jackknifing risks in tight spaces. Aircraft dollies let you reposition without running the engine. For hangars with particularly tight clearances, precision matters more than speed.

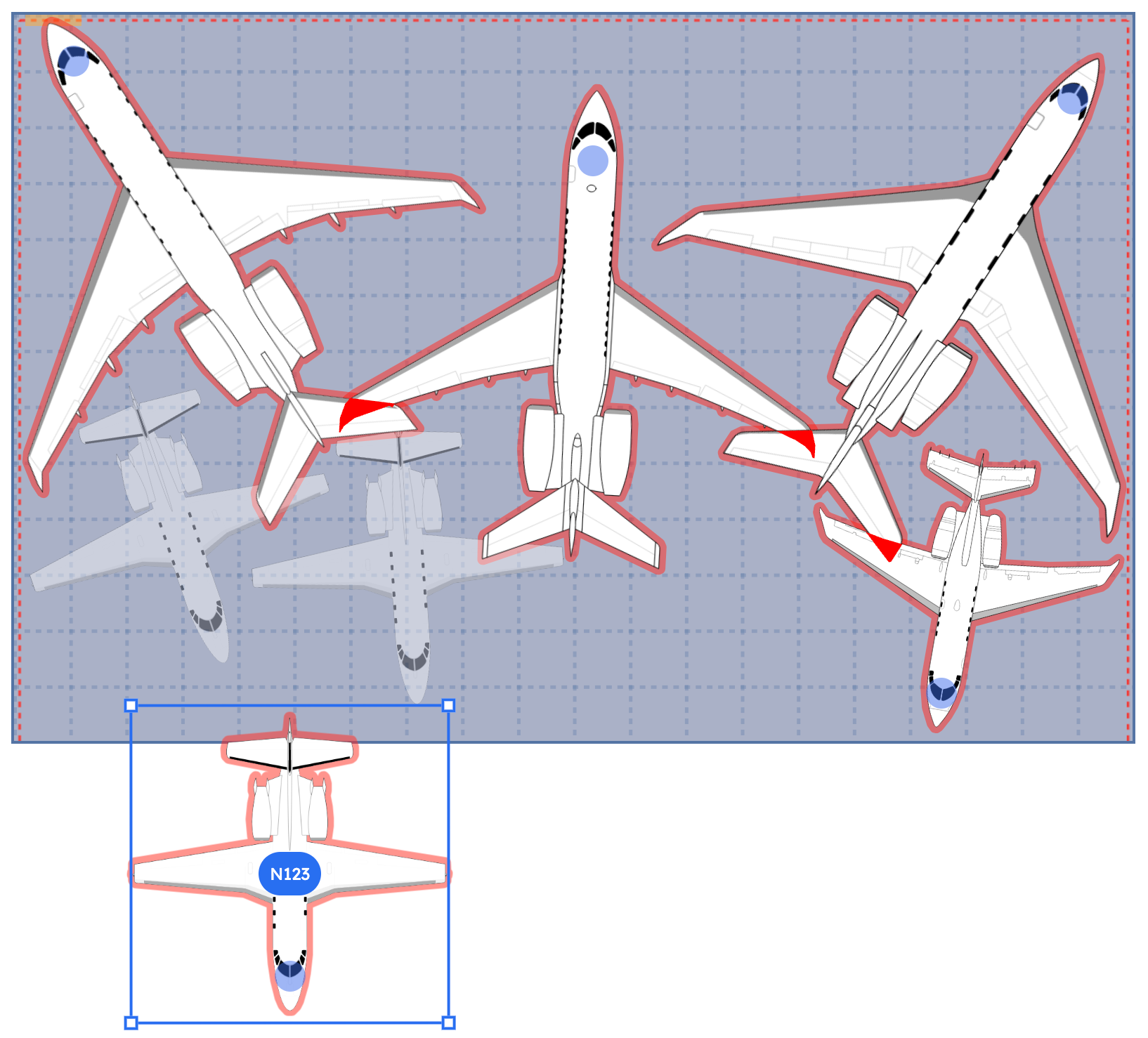

Plan your stacking. This is where software helps. When you're fitting four aircraft into a hangar with two columns and a triangular dead zone, you need to know the optimal positions before anyone starts a tug.

AirPlx's 3D visualization lets you model your actual hangar geometry—columns, angled walls, door clearances, everything. You input the obstacles once, and the system calculates safe positions for each aircraft configuration you're likely to see. The result: your line crew knows exactly where each plane goes before they start the tug. No guessing, no "let's try it and see." FBOs using systematic 3D stacking report reducing aircraft moves by 60% and cutting ground incidents significantly.

AirPlx models your actual hangar geometry—columns, irregular walls, and all

AirPlx models your actual hangar geometry—columns, irregular walls, and all

The Business Reality

Direct aircraft ground damage costs exceed $1.2 billion annually in the US alone. Factor in downtime, lost revenue, and insurance premium increases, and industry estimates put the total near $5 billion.

For an individual FBO, one incident involving composite damage can mean:

- $50,000-$100,000 in repair costs

- 2-6 months of aircraft downtime

- Increased insurance premiums

- Customer relationship damage

As Mann notes, client trust is often the biggest cost—not the repair bill itself.

Ground damage is largely preventable. Proper planning, standardized procedures, and tools that help you visualize clearances before moving aircraft can dramatically reduce incidents.

If you're dealing with columns, weird angles, or converted buildings, the first step is understanding exactly what you're working with. The second is having a system that accounts for it every time you position an aircraft.

See how AirPlx handles challenging hangar layouts

Our 3D visualization models your actual hangar geometry—columns, irregular walls, door clearances, and all. See optimal aircraft positions before anyone starts a tug.