5 Best Practices for Aircraft Hangar Optimization

Published on April 28, 2025 • 5 min read

Picture this scenario: you're staring at a packed hangar, about to turn away a $2.8 million Citation because you can't find 2,500 square feet of space. This frustration is widespread—71% of airports report individual hangar shortages, with 72% of aircraft owners waiting 6 months to 2+ years for hangar space.

Aviation faces a supply-demand crisis. Business jet deliveries reached 712 aircraft globally in 2022, with the U.S. market accounting for nearly 70%. Each new aircraft requires approximately 5,000 square feet of hangar space. That's 2 million square feet of new hangar demand annually—just for new deliveries. Factor in the 81% increase in larger aircraft (tail heights over 24 feet) since 2010, and the space crunch becomes critical.

1. Master Vertical Space Utilization

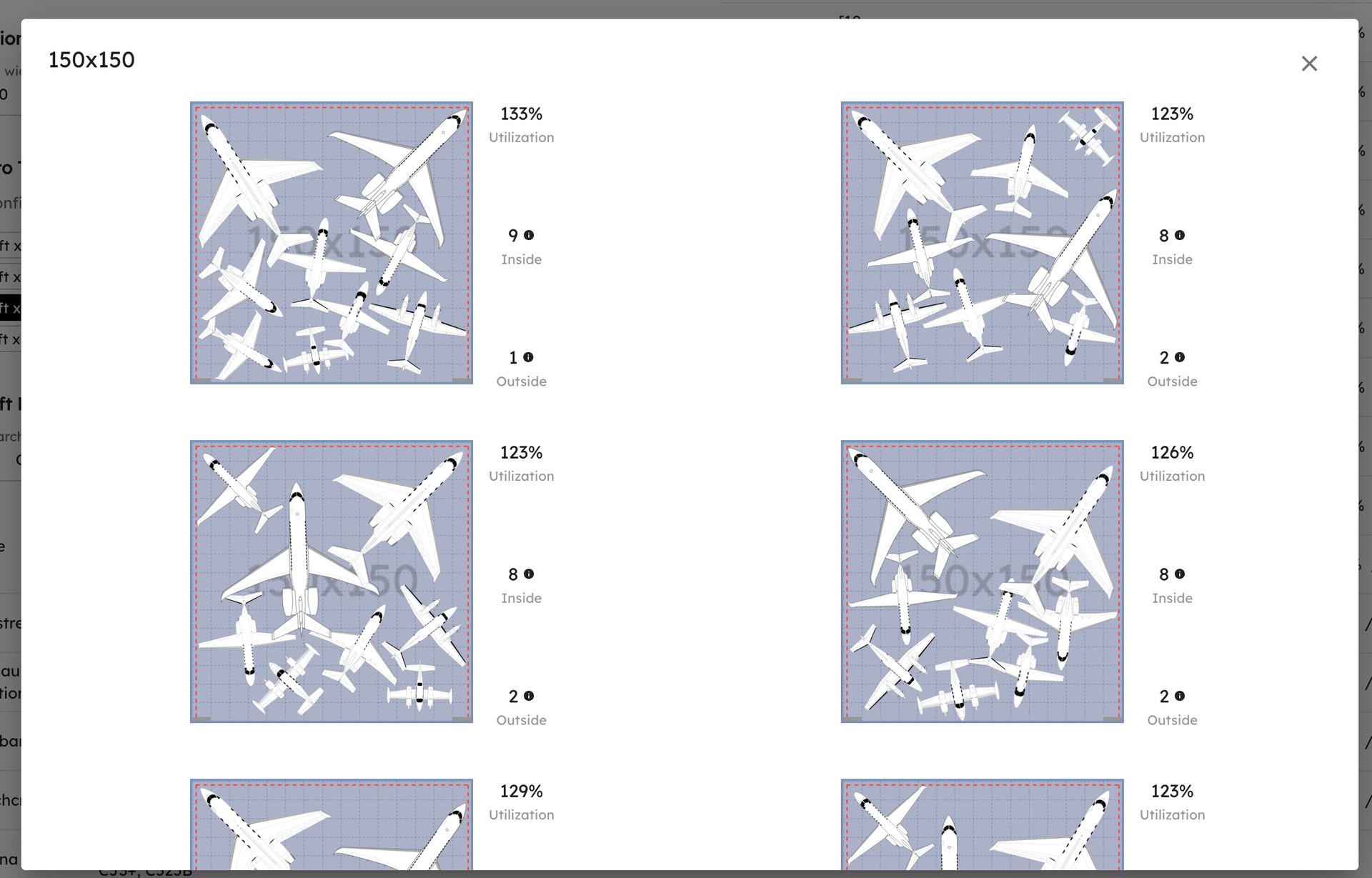

Most FBOs miss a crucial point: You're not managing floor space—you're managing volume. With modern business jets like the Gulfstream G650 requiring 12,000-14,000 square feet and the upcoming Dassault Falcon 10X needing 15,625-20,000 square feet, thinking in 2D is leaving money on the table. 3D aircraft stacking is the solution to maximizing this vertical space efficiently.

Forward-thinking operators are implementing cantilever rack systems and multi-level storage solutions, focusing on maximizing vertical space while maintaining accessibility. Door height is critical: Ensure your hangar doors are at least 28 feet high—many older facilities with 24-foot doors are already obsolete for modern jets.

Implementation considerations: Before installing vertical storage systems, factor in FAA Part 139 requirements for fire suppression systems. Overhead structures trigger additional sprinkler head requirements—budget $15-25K per zone. Your insurance carrier will want to inspect any modifications. Start with a pilot zone in your least critical area, and plan for 2-3 weeks of reduced capacity during installation.

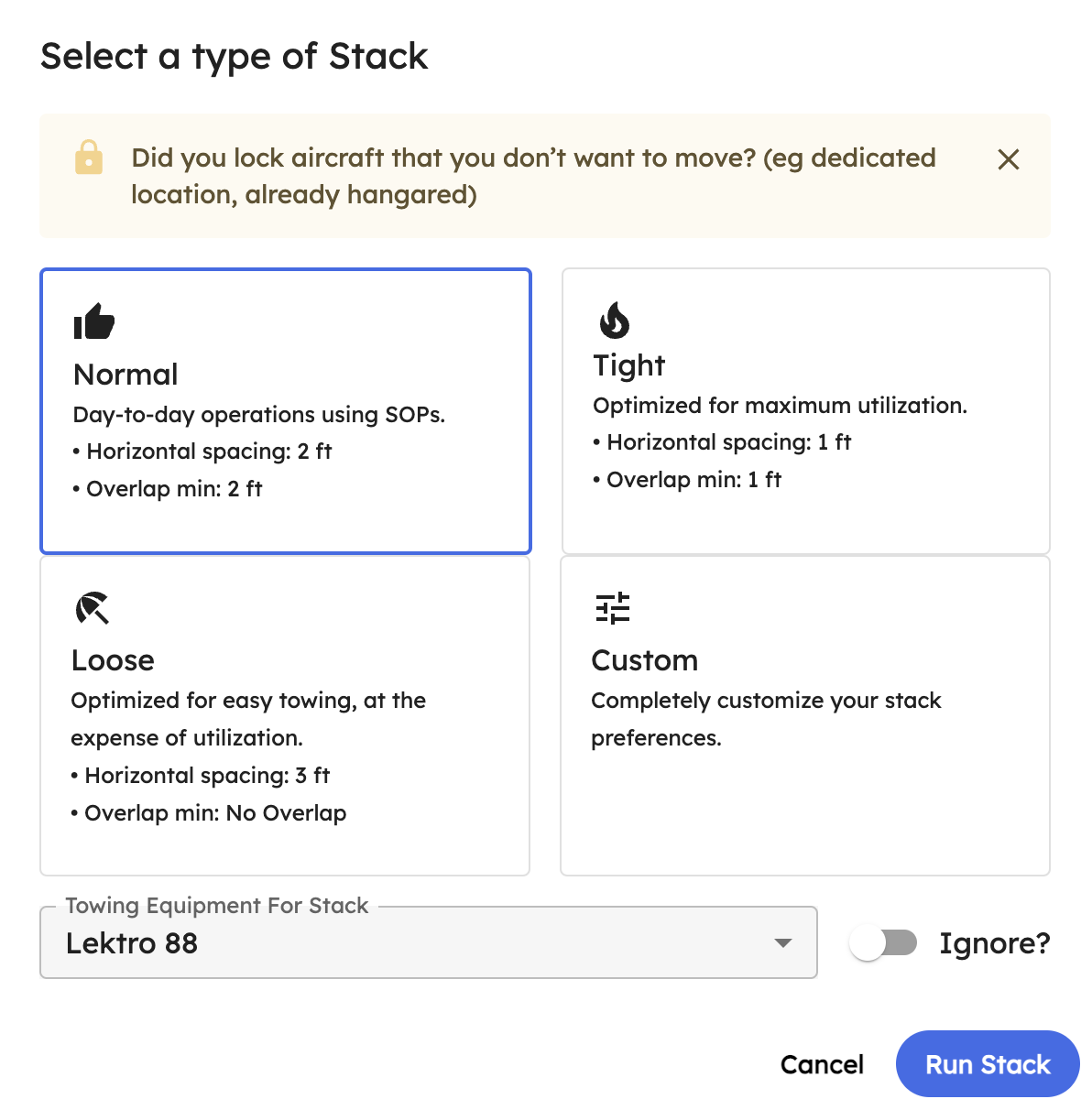

Advanced 3D stacking algorithms can increase hangar capacity by 35-40% without adding square footage

2. Embrace Data-Driven Layout Optimization

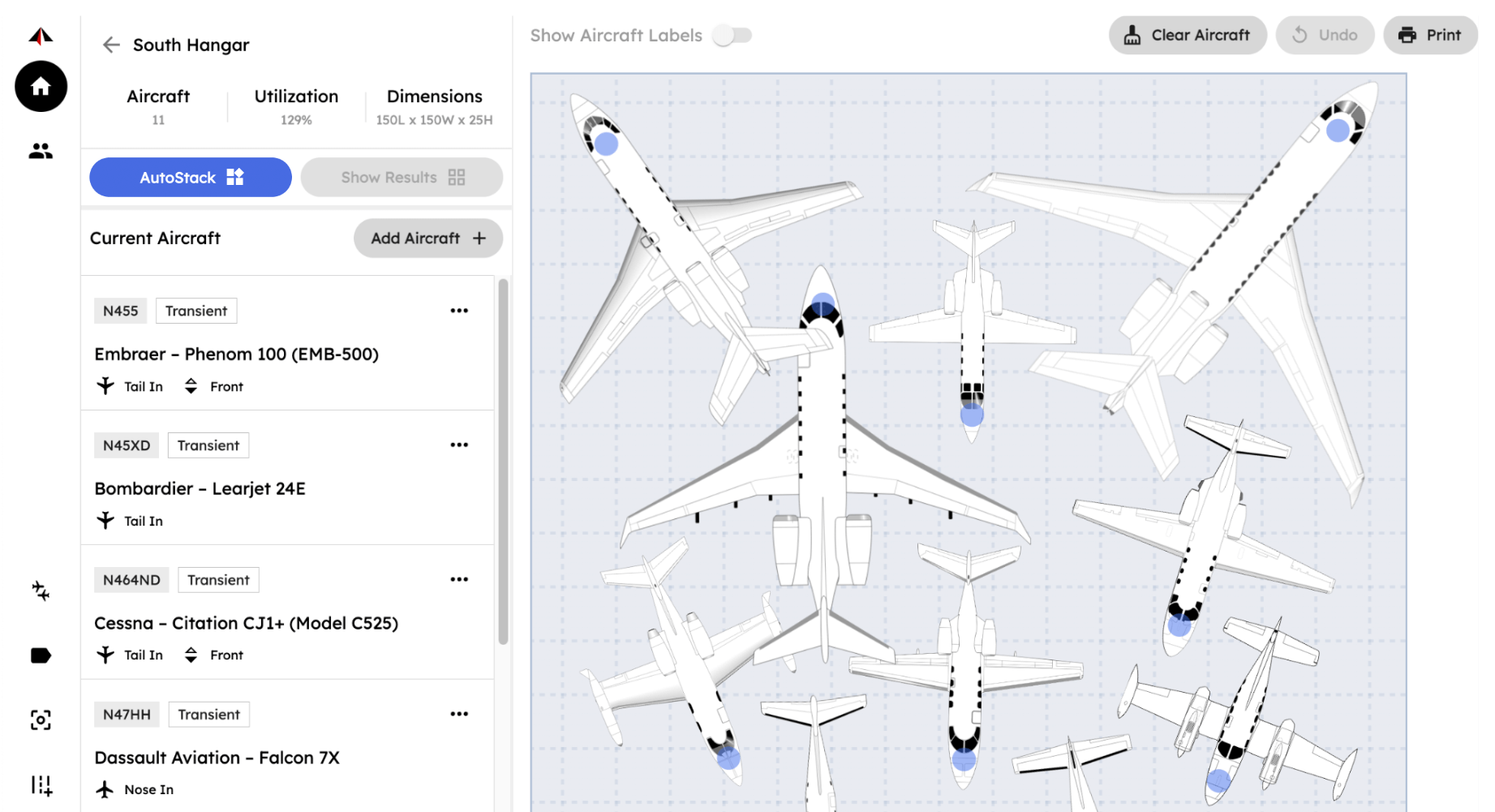

Managing aircraft placement shouldn't be guesswork with million-dollar assets. The FAA's 2024 infrastructure investment of $246 million signals a push toward modernization, including how we approach hangar layouts. Leading FBOs are abandoning "that looks about right" in favor of precision placement using automated optimization tools.

Your aircraft are worth more than game pieces

Your aircraft are worth more than game pieces

Real-world example: A Texas FBO serving both turboprops and jets discovered their manual layouts were achieving only 62% space efficiency. After implementing automated stacking algorithms, they increased to 87% utilization—equivalent to adding a 10,000 square foot hangar without breaking ground. The software accounts for aircraft dimensions, tug paths, maintenance access, and even seasonal traffic patterns. (Learn more about the financial impact of hangar stacking automation)

Additional considerations: Higher utilization means more aircraft movements. That Texas FBO also had to hire two additional line technicians ($120K annually) and invest in a second aircraft tug ($85K). (Selecting the right tugs is crucial for efficient high-density operations.) Factor in 25% higher insurance premiums due to increased aircraft density. The optimization paid for itself in 14 months, but budget for these operational realities upfront.

3. Create Dynamic Zoning Systems

Static layouts no longer suffice. With hangar rent becoming FBOs' second-largest revenue stream as fuel margins shrink, flexibility is essential. Smart operators are creating modular zones that adapt to changing fleet compositions.

Essential zones to implement: Heavy maintenance bays with reinforced flooring and 440V power (typically 20% of space), transient parking near doors (30%), long-term storage in rear sections (40%), and flex space for seasonal overflow (10%).

Retrofit Strategy: Installing retractable power drops and compressed air lines on 30-foot grids costs $50K upfront but prevents $200K renovations later. The reality is that you'll need to shut down 25% of your hangar for 10-14 days during installation. Schedule during your slowest month, maintain emergency power access, and have backup arrangements with neighboring FBOs. Coordinate with your electrician to work around existing aircraft—some owners won't move their jets for construction.

Customer Management: Before reconfiguring zones, review every hangar contract. Many long-term agreements include "preferred location" clauses. You may need to negotiate with 3-4 key customers before implementing changes. Build in 60-90 days for customer negotiations—rushing this process damages relationships and revenue.

Real-time analytics dashboard tracking key performance metrics for optimized hangar operations

4. Track the Metrics That Matter

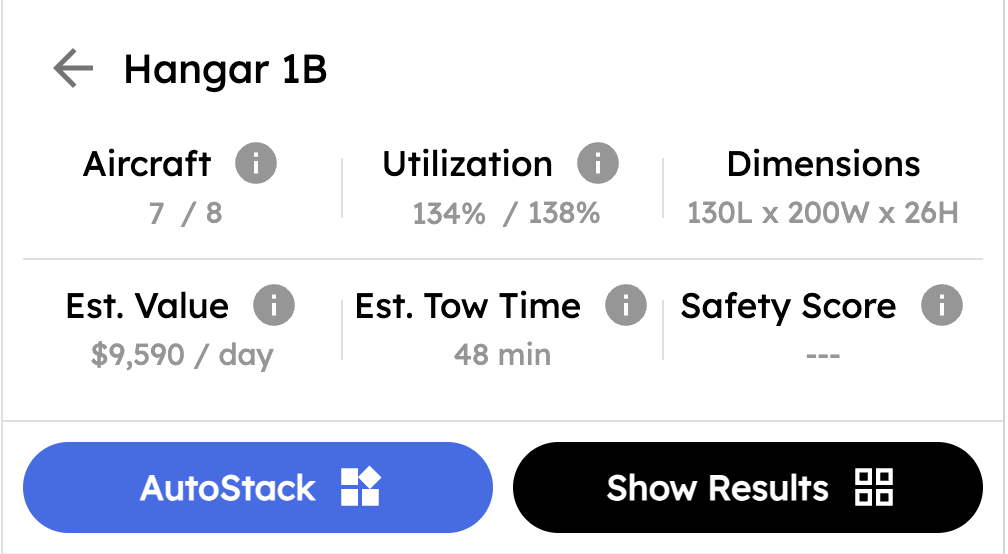

Most FBOs track occupancy, but sophisticated operators track revenue per cubic foot. With new 30,000 square foot hangars costing $9-13 million to build, vanity metrics are a luxury you can't afford. Sky Harbour Group reports their facilities operate at 68% occupancy—but that's physical occupancy, not revenue optimization.

Critical KPIs for 2025: Revenue per cubic foot (target: $0.85-1.20/month), aircraft movement efficiency (moves per labor hour), dwell time by aircraft category, and power/GPU utilization rates. One Florida operator discovered 25% of their "occupied" space was aircraft awaiting maintenance parts—they now charge progressive storage fees after 30 days, increasing revenue 18% without adding capacity. (For more on revenue optimization strategies, see our FBO ramp revenue optimization playbook)

Operational Tracking System: Set up daily movement logs tracked by your line crew. Key metrics: aircraft in/out times, tug hours per movement, GPU runtime, and any blocking incidents. Your insurance carrier may require documentation of aircraft movements for claims—this data becomes critical during incident investigations.

Progressive Fee Implementation: The Florida operator's success came with relationship management challenges. They introduced the new fee structure with 90-day notice, grandfathered existing customers for 6 months, and created a "maintenance bay" exception for customers using their shop. Result: Only 2 customers left, and maintenance revenue increased 31% as customers prioritized work completion.

5. Future-Proof Your Infrastructure

The next wave is approaching rapidly. With the FAA investing heavily in Advanced Air Mobility (AAM) infrastructure, your hangar needs to accommodate not just today's Gulfstreams but tomorrow's eVTOLs. Forward-thinking facilities are already installing DC fast-charging infrastructure and reinforcing rooftop helipads.

Immediate actions: Upgrade to LED lighting with occupancy sensors (30% energy savings), install IoT sensors for real-time space monitoring, and most importantly—invest in hangar management software. FBO Partners launched their cloud-based HangarIT platform in 2024 because even sophisticated operators were managing multi-million dollar assets with Excel spreadsheets. When a single wide-body position can generate $25,000 monthly, inefficiency becomes expensive.

Infrastructure Investment Reality: LED upgrades average $2-3 per square foot installed, but factor in 3-5 days of reduced lighting during installation. IoT sensors require reliable internet infrastructure—many hangars have poor WiFi coverage. Budget $15-20K for enterprise-grade networking before sensor installation. Staff training is essential before implementing new technology. A $50K software investment is worthless if your line crew doesn't use it consistently.

The Regulatory and Insurance Reality

Before implementing any optimization strategy, understand the compliance framework. FAA Part 139 governs hangar operations at commercial airports, requiring specific emergency egress paths, fire suppression systems, and structural load calculations. Any layout changes affecting these systems need airport authority approval—a 60-90 day process.

Insurance considerations are equally critical. Higher aircraft density increases your liability exposure. Most carriers require:

- Minimum 15-foot spacing between aircraft (non-negotiable)

- Updated fire suppression systems for modified layouts

- Structural engineering certification for any load changes

- Staff training documentation for new procedures

Critical step: Involve your insurance broker early. They can often expedite reviews and may offer premium discounts for certified optimization systems. One Colorado FBO saved $18K annually in premiums by implementing a certified aircraft tracking system.

Current Market Reality

In major markets like Los Angeles, Teterboro, and Miami, hangars operate at capacity. Construction costs make new builds economically challenging, leaving optimization as the primary solution. The difference between 68% and 95% utilization in a 50,000 square foot hangar represents $1.5 million in annual revenue at current rates.

Start with one zone. Measure everything. Then scale what works. While your competitors are turning away business, you'll be fitting that extra G650 and banking the revenue.

Implementation Support

AirPlx AutoStack transforms these best practices into actionable solutions. Our hangar stacking software has helped FBOs increase capacity by up to 40% without additional square footage, turning hangars from simple parking areas into optimized profit centers.