Aviation Industry Trends 2025: The $10 Billion Hangar Problem

Published on April 7, 2025 • 5 min read

Ramp accidents cost airlines $10 billion annually—27,000 incidents causing 243,000 injuries, according to IATA and the Flight Safety Foundation. At the same time, 71% of general aviation airports report critical hangar shortages, with waitlists exceeding 70 pilots at some locations.

These problems are connected. Poor hangar management leads to rushed aircraft movements, cramped conditions, and expensive mistakes. Managing million-dollar jets in tight quarters inevitably leads to costly incidents.

Why 2025 Marks Hangar Management's Breaking Point

The data reveals a stark reality. General aviation is experiencing unprecedented growth—the number of people learning to fly has nearly doubled since 2020. Honeywell forecasts 8,500 new business jets worth $280 billion will be delivered by 2033. Yet hangar construction costs have more than doubled in 20 years, now reaching $60-$120 per square foot.

One FBO manager in Oregon captured the frustration perfectly: "We have 35 pilots on our waitlist. Some have been waiting for years, and they're actually going backwards as new customers jump the line." Meanwhile, a single ground collision at Melbourne International caused $2.9 million in damage—just one of thousands happening yearly.

The Real Cost of Bad Hangar Management

Consider the financial impact that concerns FBO managers:

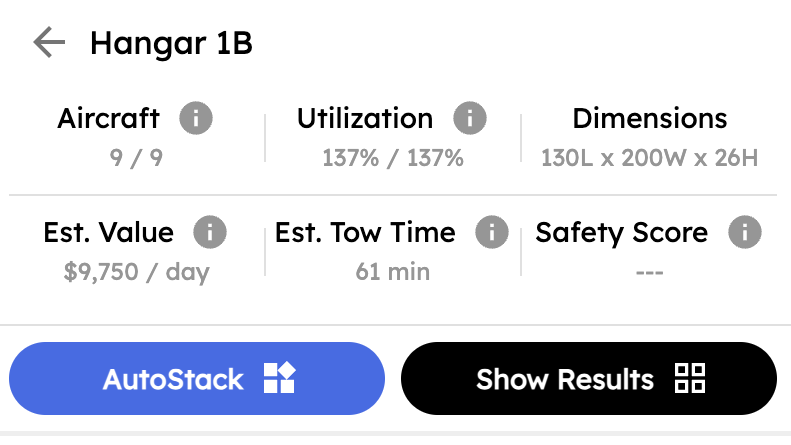

- Lost Revenue: With hangars renting at $0.40-0.70 per sq ft monthly, a poorly optimized 15,000 sq ft hangar loses $30,000+ yearly in potential income

- Ground Damage: Ground operations cause 11% of aircraft damage—one mishap can cost millions

- Customer Churn: "Arrived, reiterated our confirmed hangarage... next morning the plane was parked outside, soaking wet from overnight thunderstorm"—actual pilot quote

- Workforce Issues: "Ramp workers are all transient," leading to inconsistent service and increased damage risk

Three Game-Changing Trends Solving the Crisis

1. 3D Optimization Algorithms Now Deliver Results

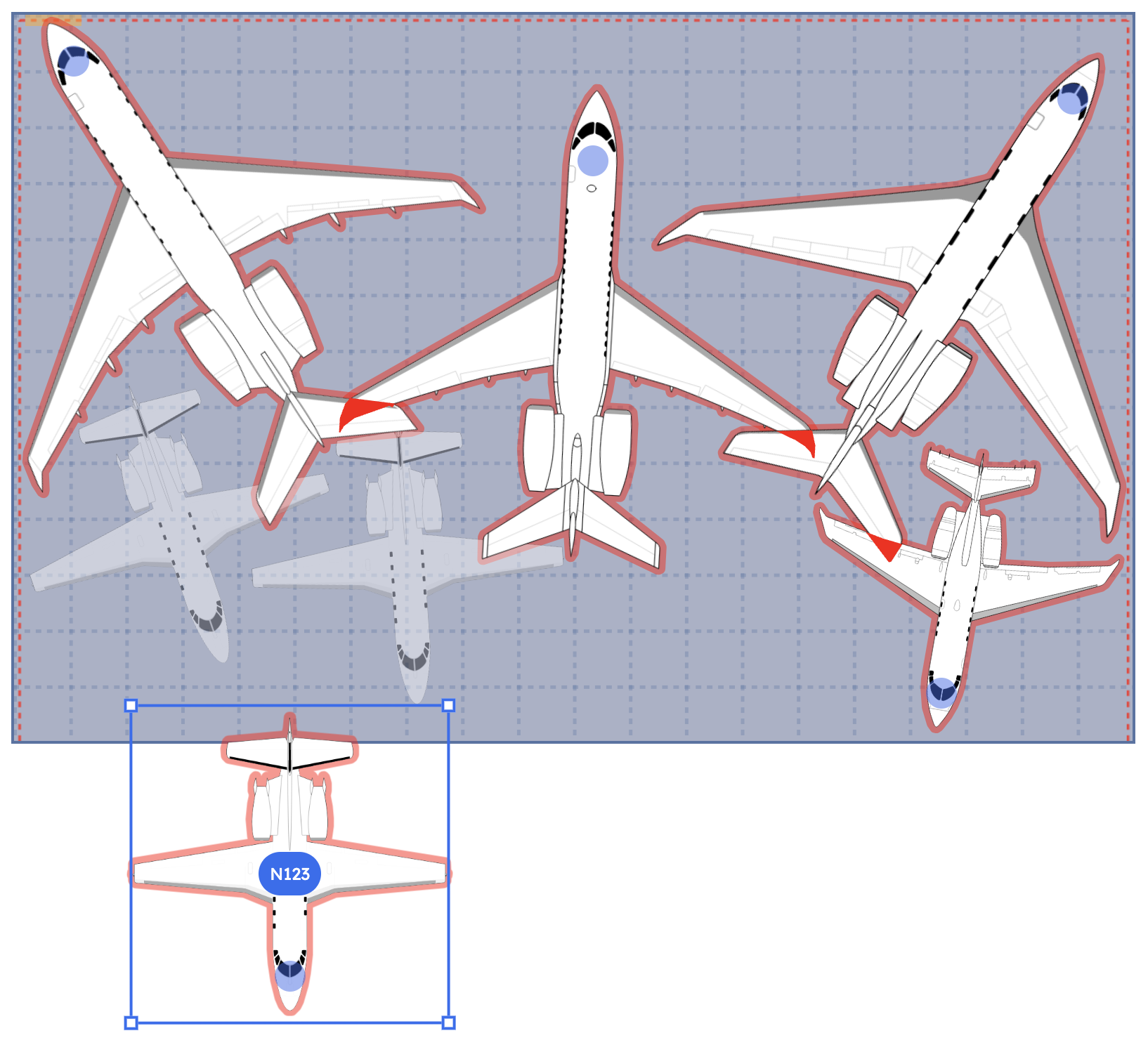

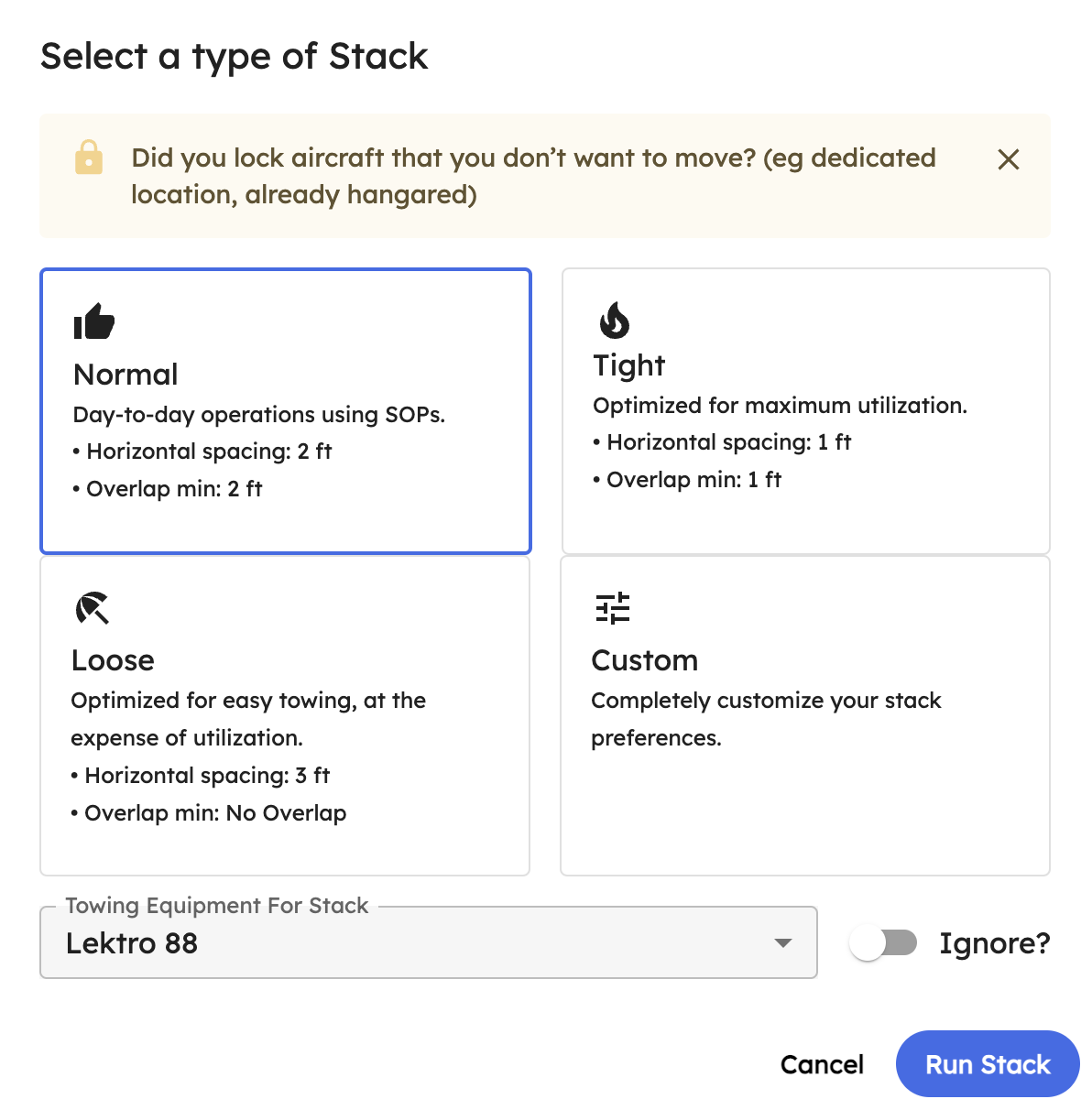

The era of managing hangars with spreadsheets and guesswork has ended. Modern AI processes aircraft dimensions, turning radii, and towing constraints in real-time. One FBO using advanced 3D stacking optimization increased capacity by 40% without adding a single square foot.

These systems think in three dimensions, considering wingtip clearances, tail heights, and seasonal traffic patterns. They solve the complex spatial puzzle that human planning simply can't optimize.

Real Implementation at Jackson Hole FBO: After installing 3D optimization software, Jackson Hole Aviation saw immediate results. "Our line crew went from spending 45 minutes planning aircraft movements to 5 minutes," says Operations Manager Sarah Chen. "The system automatically generates towing sequences that prevent bottlenecks during peak departure times."

Implementation Reality Check: The transition isn't instant. Most FBOs need 2-3 weeks for staff training and system integration. Initial setup costs range from $15,000-$50,000 depending on hangar size, but payback typically occurs within 6-8 months through increased capacity utilization.

2. Digital Twins Prevent Million-Dollar Mistakes

Virgin Australia learned this the hard way with their $2.9 million Melbourne tarmac collision. Digital twin technology now lets FBOs simulate every aircraft movement before it happens. Test new layouts, train staff, and identify collision risks—all virtually.

Scottsdale Airpark's Success Story: After implementing digital twin simulation, Scottsdale Airpark reduced ground incidents by 78% in their first year. "We can now test 'what if' scenarios without risking actual aircraft," explains GM Mike Rodriguez. "New line crew members practice in the virtual environment before touching real jets."

The Implementation Challenge: Digital twins require accurate hangar mapping and ongoing calibration. Initial setup takes 4-6 weeks and costs $25,000-$75,000. Staff need 40+ hours of training to use the system effectively. However, the technology pays for itself by preventing just one significant incident.

The return on investment is compelling: preventing just one ground incident pays for the technology many times over.

3. Integrated Cloud Platforms

Most FBOs still manage operations with "nothing more than a Rent Roll spreadsheet and a DropBox," according to industry reports. Cloud-based platforms are transforming operations by integrating:

- Real-time space optimization with billing systems

- Towing schedules with collision prevention alerts

- Weather data with automated aircraft shuffling

- Maintenance schedules with space allocation

Teterboro's Integration Success: Atlantic Aviation at Teterboro implemented a fully integrated cloud platform in 2024. "The system automatically adjusts hangar assignments based on weather forecasts," says Operations Director Lisa Park. "When storms approach, it pre-positions aircraft and optimizes space for maximum protection."

The Hidden Costs: Cloud platform integration typically requires 3-6 months of implementation time, staff training for all shifts, and ongoing subscription costs of $500-$2,000 monthly. Legacy system data migration can be complex, often requiring manual cleanup of years of inconsistent records. However, the operational efficiency gains typically justify costs within the first year.

Common Pitfalls to Avoid:

- Underestimating staff training time (budget 60+ hours per employee)

- Inadequate internet infrastructure (requires dedicated high-speed connections)

- Resistance to change from experienced line crew (plan for gradual rollout)

- Integration challenges with existing fuel systems and billing software

Implementation Guide: From Evaluation to Go-Live

Vendor Evaluation Framework

Financial Stability Assessment:

- Minimum 5 years in aviation software market

- Client references from similar-sized FBOs

- Clear upgrade path and long-term development roadmap

- Transparent pricing with no hidden integration fees

Technical Due Diligence:

- API compatibility with existing systems (fuel, billing, scheduling)

- Data security compliance (SOC 2, cybersecurity insurance)

- Disaster recovery and backup procedures

- Mobile app functionality for line crew

Operational Fit Analysis:

- Customization capability for unique hangar configurations

- Staff training requirements and ongoing support structure

- Integration timeline that works with seasonal operations

- Scalability to handle growth and additional locations

90-Day Implementation Timeline

Days 1-30: Foundation Phase

- Complete system setup and data migration

- Hangar mapping and aircraft specification input

- IT infrastructure upgrades (network, hardware, security)

- Initial supervisor training and certification

Days 31-60: Training and Testing

- All-hands training sessions for line crew

- Parallel operation with existing processes

- Daily performance monitoring and adjustment

- Standard operating procedure development

Days 61-90: Full Deployment

- Complete transition to new system

- Performance optimization based on real-world data

- Staff feedback integration and process refinement

- Success metrics establishment and reporting

Success Metrics to Track

Operational Efficiency:

- Aircraft movement time reduction (target: 30% improvement)

- Hangar utilization increase (target: 25% capacity improvement)

- Ground incident reduction (target: 50% fewer incidents)

- Customer satisfaction scores (target: 15% increase)

Financial Performance:

- Revenue per square foot improvement

- Customer retention rate increase

- Operational cost reduction

- Return on investment timeline

The Reality Check: What Technology Can't Fix (Yet)

Before you start shopping for hangar management software, understand the limitations. These systems excel at optimizing space and preventing collisions, but they can't solve every operational challenge:

Labor Shortage Impact: Even the smartest algorithm can't work with understaffed operations. "We have the technology to optimize everything perfectly," explains Tom Mitchell, GM at Denver's Centennial Airport. "But when you're short two line crew members during peak season, the best software in the world can't move aircraft by itself." Learn more about FBO staffing challenges.

Staffing Solutions That Work:

- Cross-training programs: Train customer service staff in basic line operations

- Seasonal partnerships: Share resources with nearby FBOs during peak periods

- Technology-assisted training: Use simulation for faster new employee onboarding

- Predictive scheduling: Use historical data to optimize staffing patterns

Weather Still Wins: Severe weather events can disrupt even the most sophisticated systems. Ice storms, wind shear, and unexpected maintenance issues require human judgment that technology supplements but can't replace. Prepare your FBO for hurricane season with comprehensive planning.

Emergency Protocol Integration: Modern systems now include severe weather modules. "When tornado warnings hit, our system automatically generates emergency evacuation sequences," explains Rebecca Martinez, Operations Manager at Will Rogers World Airport. "It considers aircraft value, fuel load, and evacuation time to prioritize which aircraft get hangar protection first."

Change Management Hurdles: The biggest barrier isn't technical—it's cultural. "Our crew had been doing things the same way for 15 years," says one FBO manager. "Getting them to trust a computer system to tell them where to park aircraft was the hardest part of implementation."

Proven Change Management Strategies:

- Champion identification: Select respected crew members as early adopters

- Gradual rollout: Start with less critical operations before peak periods

- Success celebration: Publicly recognize efficiency improvements and safety wins

- Feedback incorporation: Adjust system parameters based on crew recommendations

ROI Timeline Reality: While the technology pays for itself, expect 12-18 months for full ROI realization. Initial productivity may actually decrease during the learning curve period.

Your Strategic Options in 2025

The aviation industry added 1.3 million jobs and generates $339 billion in economic output. The FBO market alone will reach $42.7 billion by 2033. However, this growth faces a significant constraint: physical space.

With 71% of airports facing hangar shortages and construction costs skyrocketing, the winners won't be those who build more—they'll be those who optimize what they have. The choice is straightforward:

- Option A: Build a new 15,000 sq ft hangar for $1.8 million (if you can find land and permits)

- Option B: Optimize your existing hangar to fit 40% more aircraft for a fraction of the cost

Explore the ROI of hangar stacking automation to understand the financial impact of optimization.

Smart FBOs are choosing optimization. They're converting waitlists into revenue, preventing costly accidents, and fulfilling their hangar commitments.

Maximize Your Hangar Revenue

AirPlx's AutoStack provides proven technology that FBOs use to fit more aircraft, prevent costly damage, and convert waitlists into revenue. Our 3D optimization algorithms consider every constraint: turning radii, wingtip clearances, seasonal patterns, and your specific towing equipment.

Potential impact: A typical 15,000 sq ft hangar optimized with AirPlx can generate an additional $180,000-$300,000 annually.