AirPlx Mirrors Your SOPs in Feet (or Meters!)

Published on September 15, 2025 • 4 min

Walk into any FBO and you'll find SOPs—but they're not just policy documents gathering dust in a binder.

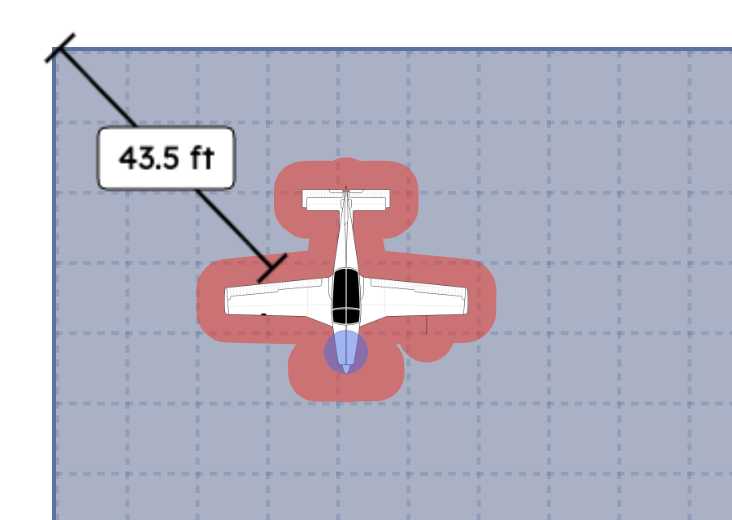

They're precise measurements: 2 feet between aircraft tails, 10 feet minimum on the ramp, nose-in positioning at exactly 15 feet versus 25 feet for different aircraft types.

These seemingly small distances matter more than most people realize. Hangar rash incidents start at around $27,000 for basic propeller strikes and can reach $260,000 or more for major damage, according to 2024 aviation insurance data.

Why Distance-Based SOPs Matter

The FAA's Advisory Circular 00-34B makes this clear: standardized spacing and positioning procedures are critical for preventing ground incidents and protecting both personnel and aircraft during operations.

Your SOPs exist to replace guesswork with consistent procedures. When line service knows exactly how much space to leave, they work more confidently in tight quarters. And the spacing stays the same whether your most experienced tech is working or someone newer is on shift.

NATA's operational best practices say every FBO needs "specific and clear guidance with procedures applicable to its own operation." But there's often a big gap between what's written in the manual and what actually happens on a busy ramp.

We built AirPlx to help operators translate their spacing requirements into visual layouts

The Challenge

When the weather's moving in fast and you need to fit three Citations and a King Air in the hangar, that's not the time to be explaining why your facility uses 2-foot spacing instead of 4-foot spacing.

Yet that's exactly when things go wrong. Hand-drawn layouts (yes, even the ones sketched in Microsoft Paint) can't capture the precision your SOPs require. New crew members might know the general rules, but do they know your specific hangar's quirks and spacing requirements?

Here's what the data shows: ground handling incidents make up 64% of worldwide aviation incidents according to global loss-adjusting company McLarens, and represent 63% of all aviation insurance claim values. When you consider that ground damage costs start at $27,000 and often exceed $260,000, the disconnect between written procedures and daily practice becomes a real financial issue.

Moving from hand-sketched layouts to measured, consistent positioning

How AirPlx Encodes Distances

When we visit FBOs, we often find the same pattern. Operations managers know their spacing requirements intimately, but that knowledge lives in people's heads rather than in systematic documentation. Here's what we typically encounter:

- Insurance-mandated spacing (typically 2-4 feet between aircraft depending on coverage)

- Operational positioning preferences (nose-in for fuel access, tail-in for maintenance)

- Facility-specific clearances (space around columns, doors, equipment)

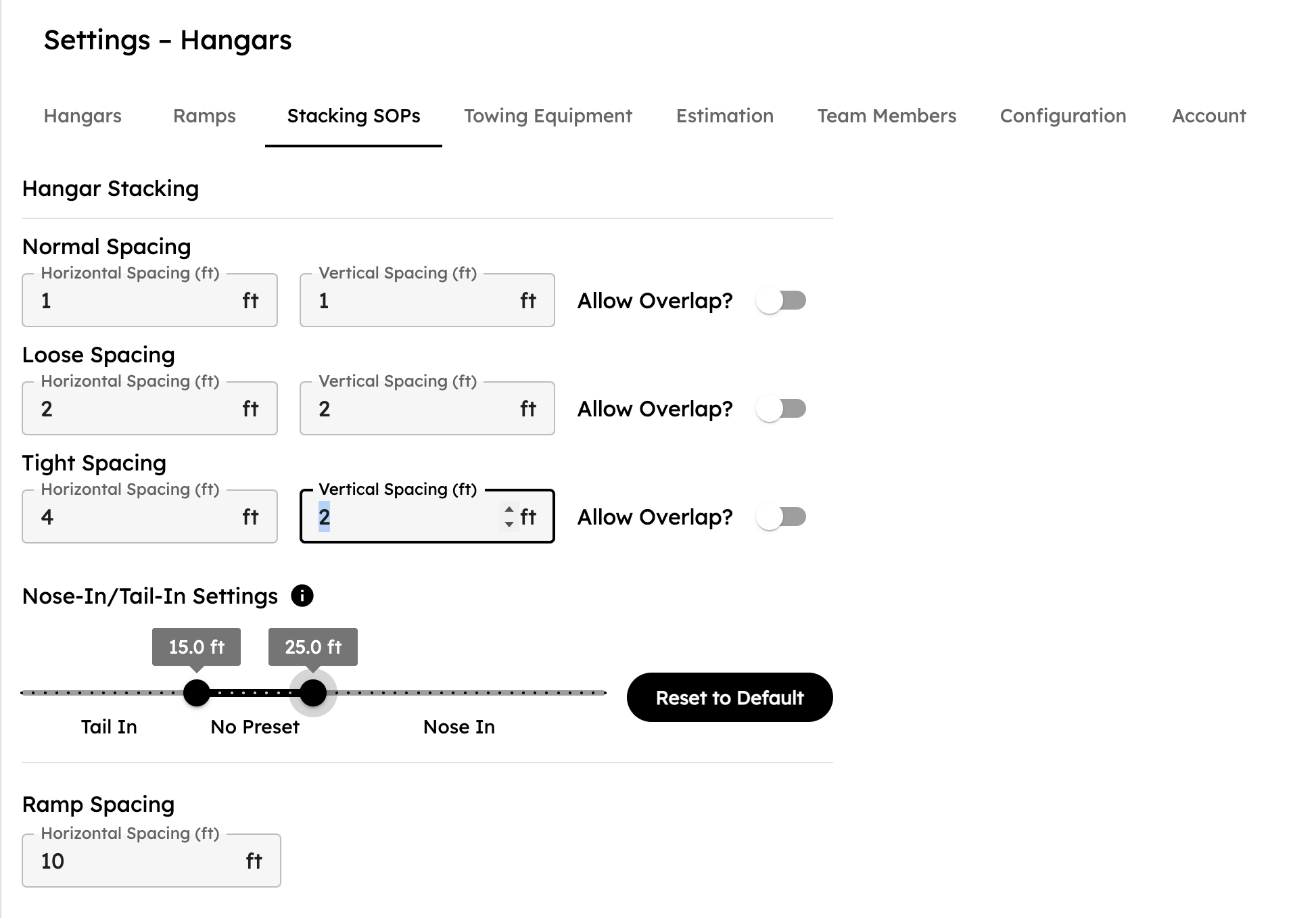

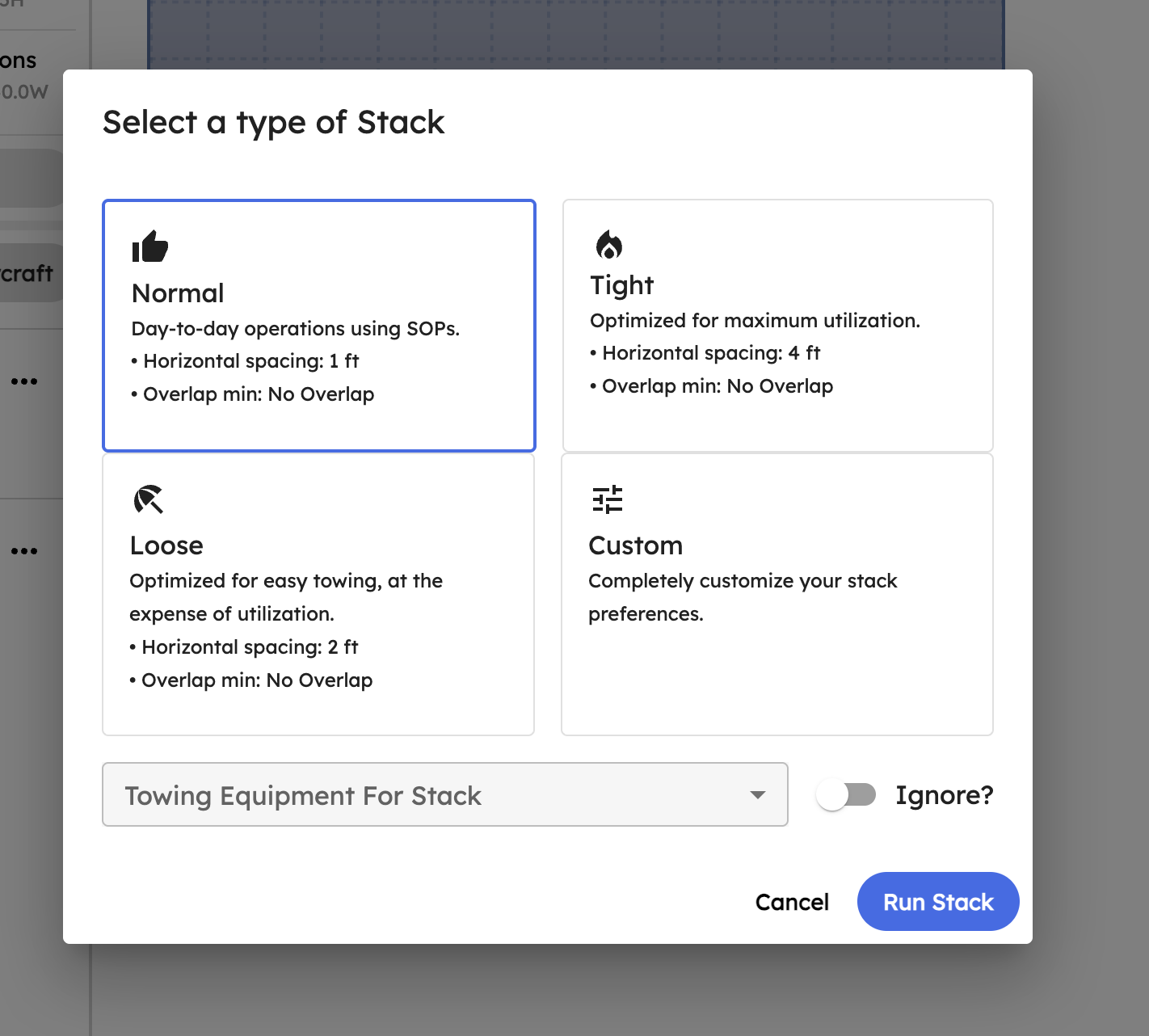

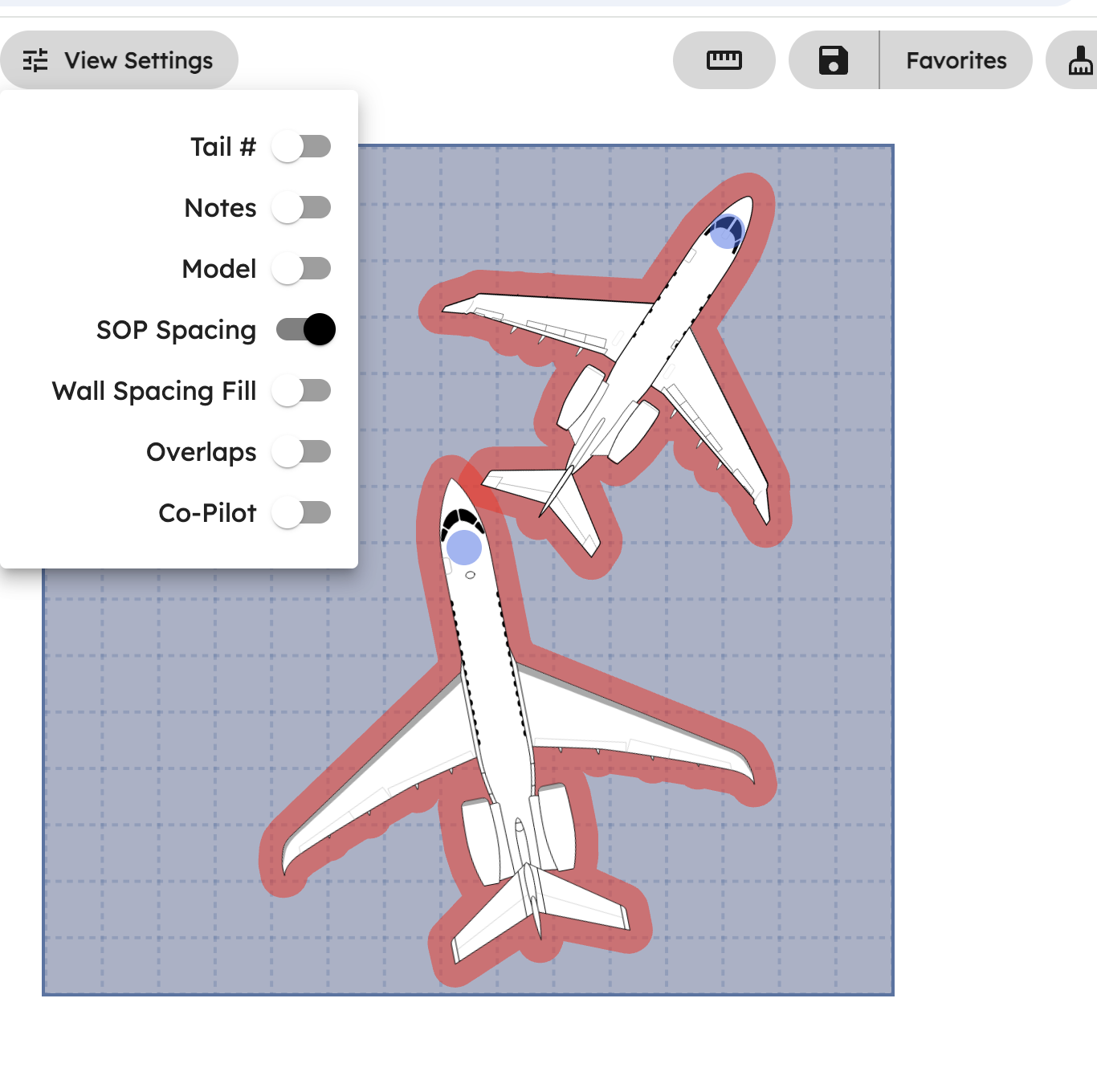

The software handles this by letting you specify:

- Spacing configurations that match your insurance and safety standards

- Positioning rules based on aircraft type and operational needs

- Obstacle mapping for your specific facility layout

From our experience, the real value isn't about cramming more planes into tight spaces—it's about eliminating the inconsistencies that happen when busy line crews are eyeballing distances or trying to remember whether this hangar uses 2-foot or 3-foot spacing.

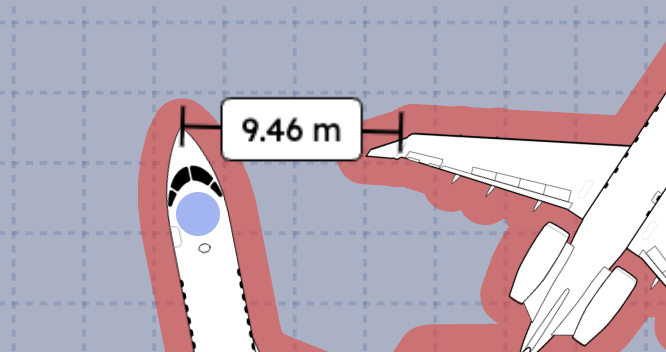

Using measurement tools to convert written spacing policies into visual layouts

The system works with whatever measurement units your team prefers—feet, meters, or both

The Business Case

Safety Value: When you consider that ground handling incidents typically start around $27,000 for basic propeller strikes and can reach $260,000 or more for serious damage, even modest improvements in positioning consistency can have financial value.

Operational Consistency: Visual layouts can help crews position aircraft more consistently, which tends to be most valuable during busy periods when time pressure sometimes leads to shortcuts.

Training Support: Visual layouts can help new staff understand spacing requirements faster than reading procedure manuals, though how much time this actually saves depends on how you currently train people.

Capacity Optimization: The potential value comes from using available space more systematically. How much this matters depends on your current positioning efficiency and whether you're actually constrained by space. Learn about hangar optimization best practices and explore 3D stacking strategies. Calculate your ROI on optimization investments.

Consistent spacing whether you're slammed on a holiday weekend or it's a quiet Tuesday

The Reality of Implementation

What You Actually Need: Your hangar dimensions (which you probably have) and a clear understanding of your current spacing rules (which you might need to document). Most FBOs know their SOPs but haven't translated them into specific measurements.

The Hard Part: Getting your line service team to trust computer-generated layouts instead of their own experience. We've seen this take anywhere from a few weeks to several months, depending on how willing people are to change established habits. Software can't fix resistance to change—that's a management challenge.

Timeline: Honestly, it depends on how well-documented your current procedures are and how open your team is to trying something new. Some operations are ready to go quickly, others spend months just figuring out what their actual spacing requirements should be.

Honest Cost Discussion: Subscription pricing varies based on complexity, but the real cost is change management. Your team needs to buy into new ways of working, or the software becomes expensive shelf-ware.

When It Makes Sense: If you're having consistent problems with aircraft positioning, dealing with space utilization challenges, or need to standardize procedures across shifts. If your current informal system works reliably and your team is happy with it, adding software complexity might not be worth the hassle.

What We've Learned: The facilities that get the most value are usually the ones with multiple shifts, varying staff experience levels, or complex hangars where small positioning mistakes create big problems. Simple operations with experienced, stable crews often don't see enough benefit to justify the change.

Sources:

- FAA Advisory Circular 00-34B: Aircraft Ground Handling, Servicing, and Marshalling

- National Air Transportation Association (NATA) Operational Best Practices

- Global Aerospace: From the Hangar to the Tarmac - Rising Trends in Ground Incidents (McLarens data)

- ICAO Manual on Ground Handling (Doc 10121)