The 10 Largest Hangars in North America by Usable Footprint

Published on February 17, 2026 • 5 min read

Most "biggest hangar" lists on the internet are useless. They mix campus totals with single buildings, count office space as hangar floor, and swap square footage numbers between facilities like a shell game.

We wanted something better. So we went to primary sources: federal records, military base public affairs offices, NASA reuse guidelines, operator press releases, and structural engineering firms. The ranking below uses one metric: usable clear-span footprint, meaning the obstruction-free floor area inside a single hangar building where you can actually park aircraft.

Here are the 10 largest hangars in North America, ranked by that number.

The Rankings at a Glance

| Rank | Hangar | Location | Usable Footprint | Year Built |

|---|---|---|---|---|

| 1 | Goodyear Airdock | Akron, OH | 364,000 sq ft | 1929 |

| 2 | Hangar No. 1 (Lakehurst) | Lakehurst, NJ | 336,350 sq ft* | 1921 |

| 3 | Hangar One (Moffett) | Mountain View, CA | 323,062 sq ft | 1933 |

| 4 | Steel LTA Hangar (Weeksville) | Elizabeth City, NC | 314,880 sq ft* | 1942 |

| 5 | Hangar 2 (Moffett) | Mountain View, CA | 241,110 sq ft | 1943 |

| 6 | Hangar 5 (Lakehurst) | Lakehurst, NJ | 241,000 sq ft | 1943 |

| 7 | Hangar 6 (Lakehurst) | Lakehurst, NJ | 241,000 sq ft | 1943 |

| 8 | Hangar B (Tillamook) | Tillamook, OR | 241,110 sq ft | 1943 |

| 9 | AA Hangar 2 (O'Hare) | Chicago, IL | 191,000 sq ft | 2019 |

| 10 | FedEx Airbus Hangar | Memphis, TN | 120,000 sq ft* | 2009 |

Values marked with an asterisk are estimates computed from published plan dimensions (length x width). Actual usable floor area may be lower due to internal offices, tapered walls, or non-rectangular footprints.

One pattern jumps out immediately: WWII blimp hangars dominate this list. Seven of the ten entries are lighter-than-air facilities built between 1921 and 1943. The U.S. Navy needed structures big enough to house entire fleets of patrol airships, and those buildings still dwarf most modern construction.

1. Goodyear Airdock, Akron, OH (364,000 sq ft)

The undisputed champion. Built in 1929 for $2.2 million (about $32 million in today's dollars), the Goodyear Airdock was the largest building in the world without interior supports when it was completed. It still holds that distinction nearly a century later.

The numbers are staggering: 1,175 feet long, 325 feet wide, 211 feet tall. That's 14 stories of unobstructed vertical space, supported by 13 steel arches, enclosing 55 million cubic feet of volume.

The Airdock is so massive that it creates its own weather. When humidity rises and temperatures shift, moisture condenses inside and it literally rains indoors. Workers have reportedly needed umbrellas while working inside the building.

Each door weighs 600 tons and has its own dedicated power plant. The entire structure sits on rollers to accommodate thermal expansion and contraction. Think about that: the building itself moves.

Airship hangars like these were the largest enclosed structures ever built. The Goodyear Airdock is even bigger.

Airship hangars like these were the largest enclosed structures ever built. The Goodyear Airdock is even bigger.

Key specs:

- 364,000 sq ft published obstruction-free floor space

- 325 ft clear-span width

- Semi-spherical doors (no standard W x H published)

- Originally built for rigid airship construction

2. Hangar No. 1, Lakehurst, NJ (336,350 sq ft est.)

The site of one of aviation's most famous disasters. Hangar No. 1 at what is now Joint Base McGuire-Dix-Lakehurst was completed in 1921 to house rigid airships for the U.S. Navy.

Published dimensions vary by source. The NPS lists 961 feet long, 350 feet wide, and 200 feet high. Other records give 966 feet long, 350 feet wide, and 224 feet high, with a published floor area of 211,434 sq ft. The ranking footprint of 336,350 sq ft is computed from the NPS plan dimensions and should be treated as a generous upper bound. Service mezzanines on each side and internal office areas significantly reduce the actual usable clear-span floor space. Using the published floor area of 211,434 sq ft would place this hangar below the WWII timber hangars in the rankings.

This is the hangar that housed the Hindenburg during its visits to the United States. Base history records note that clearance for the airship at bow and stern was extremely tight, a remarkable detail given the building's enormous size.

Today, the Navy still uses the structure for aviation training, including a simulated carrier deck for pilot qualification exercises.

Hangar No. 1 at Lakehurst. The Hindenburg was housed here during its visits to the United States.

Hangar No. 1 at Lakehurst. The Hindenburg was housed here during its visits to the United States.

Key specs:

- 336,350 sq ft estimated upper bound (published floor area: 211,434 sq ft)

- 350 ft clear-span width

- Massive steel doors on railroad tracks (no numeric W x H published)

- Currently military aviation training

3. Hangar One, Moffett Field, CA (323,062 sq ft)

Hangar One is the Silicon Valley landmark you've driven past a thousand times on Highway 101 without fully appreciating. Built in 1933 to house the USS Macon airship, NASA historic preservation records list its building footprint at 323,062 sq ft, roughly 8 acres under one roof.

At 1,133 feet long, 308 feet wide, and 198 feet tall, it's a building on a truly inhuman scale. The hangar's "orange peel" clamshell doors are an engineering curiosity: they open by folding outward like the sections of an orange.

The structure's recent history is almost as interesting as its origin. After decades of neglect and a toxic exterior panel removal in 2011 that left the building as a massive steel skeleton, NASA leased 1,000 acres of Moffett Field to Google's parent company Alphabet for 60 years. The total lease value: $1.16 billion. Restoration of Hangar One is part of the deal.

A tech company paying over a billion dollars for a 90-year-old hangar tells you everything about the enduring value of well-designed aviation infrastructure.

Hangar One at Moffett Field. Built in 1933 for the USS Macon airship, now undergoing restoration under Google's $1.16 billion lease.

Hangar One at Moffett Field. Built in 1933 for the USS Macon airship, now undergoing restoration under Google's $1.16 billion lease.

Key specs:

- 323,062 sq ft published building footprint

- 308 ft clear-span width

- Orange-peel clamshell doors

- Restoration underway via Google/Alphabet lease

4. Steel LTA Hangar, Weeksville, NC (314,880 sq ft est.)

The least well-known giant on this list. The Weeksville Dirigible Hangar near Elizabeth City, North Carolina was built by the Navy during WWII as part of the coastal defense lighter-than-air program.

Published dimensions are 960 feet long, 328 feet wide, and 190 feet high. Like Lakehurst Hangar No. 1, this is an estimate from plan dimensions, not a published floor area.

What makes Weeksville interesting today is its second life. The hangar is now used for commercial aerostat (tethered balloon) manufacturing and testing. The facility reportedly provides over 300,000 sq ft of production, laboratory, and test capacity.

Key specs:

- 314,880 sq ft estimated from plan dimensions

- 328 ft clear-span width

- Orange-peel doors (no numeric W x H published)

- Currently private aerostat manufacturing

5-8. The WWII Timber Blimp Hangars (241,000+ sq ft each)

Four entries on this list share essentially the same DNA. During WWII, the Navy built a standardized timber blimp hangar design at bases across the country for coastal patrol airship operations. The NASA Moffett Field Reuse Guidelines publish the standard dimensions:

- Hangar floor area: 241,110 sq ft

- Interior width: 235 ft

- Clear door width: 220 ft

- Clear door height: 120 ft

Of the original 17 wooden hangars built, only five survive. Four of them make this list:

Hangar 2, Moffett Field, CA (completed 1943). Part of the Moffett Field historic district alongside Hangar One. Modern reuse proposals emphasize its potential for large-volume industrial and storage operations.

Hangars 5 and 6, Lakehurst, NJ (completed 1943). Still actively used by the military. Hangar 5 houses UH-60 Blackhawk helicopters, among other aircraft. The Joint Base McGuire-Dix-Lakehurst public affairs office publishes 241,000 sq ft of floor space for each.

Hangar B, Tillamook, OR (completed 1943). Now the Tillamook Air Museum. It's the largest clear-span wooden structure in the world and houses a collection of WWII-era and vintage aircraft. If you're ever on the Oregon coast, it's worth the detour.

WWII blimp hangars seen from above. These standardized timber structures each cover 241,000+ sq ft of floor space.

WWII blimp hangars seen from above. These standardized timber structures each cover 241,000+ sq ft of floor space.

The 220-foot door width on these hangars is worth noting. It comfortably fits a Boeing 747-400 (wingspan: 211 ft) but cannot accommodate an Airbus A380 (wingspan: 262 ft). Door width is a hard constraint that no amount of interior space can solve.

9. American Airlines Hangar 2, O'Hare (191,000 sq ft)

The only entry on this list built in the 21st century, and it represents a completely different philosophy from the airship-era giants above it.

American Airlines' Hangar 2 at O'Hare opened in January 2019 after a three-year, $251 million construction effort. At 191,000 sq ft (some project partners cite 194,000 sq ft), it's O'Hare's largest hangar and the longest clear-span, dual-threshold airline hangar in the world.

The "dual-threshold" part is what makes this facility special. It has operable doors on both ends, creating a 528-foot opening expanse. Aircraft can enter from one side and exit the other, eliminating the taxi-in/back-out choreography that eats up time at single-entry hangars. The clear door height is 70 feet, with 85 feet of internal clearance.

That design choice is pure throughput optimization. American can service two 777s simultaneously, or six 737s, or various combinations depending on the maintenance schedule. Planes flow through instead of stacking up.

Modern hangars prioritize throughput over raw size. Dual-entry designs like American's O'Hare facility let aircraft flow through instead of backing out.

Modern hangars prioritize throughput over raw size. Dual-entry designs like American's O'Hare facility let aircraft flow through instead of backing out.

Key specs:

- 191,000 sq ft published

- 528 ft opening expanse (dual-entry)

- 70 ft clear door height / 85 ft internal clearance

- Services two 777s or six 737s simultaneously

10. FedEx Airbus Hangar, Memphis (120,000 sq ft est.)

The youngest facility on this list, completed in 2009, and it comes with one of aviation's best pivots.

FedEx originally commissioned this hangar at Memphis International Airport to maintain the Airbus A380 freighter. Then Airbus cancelled the A380F program. The structural engineers from Walter P Moore had already designed a 400-foot by 300-foot clear-span bay with 150 feet of height and 100 feet of usable clearance. So FedEx adapted: the hangar now maintains Boeing 777 freighters instead.

The 120,000 sq ft ranking value is derived from the published span dimensions (400 ft x 300 ft). Other sources describe the overall facility at 150,000 sq ft or even 303,000 sq ft, but those figures likely include attached support spaces outside the clear-span bay.

The FedEx heavy maintenance hangar in Memphis. Originally designed for the A380, it now services 777 freighters.

The FedEx heavy maintenance hangar in Memphis. Originally designed for the A380, it now services 777 freighters.

Key specs:

- 120,000 sq ft estimated from published span dimensions

- 300 ft clear-span width

- 100 ft height clearance

- Originally designed for A380, now maintains 777s

Sources and Methodology

All rankings use published clear-span floor area where available. Estimated values (marked with asterisks) are computed from published plan dimensions and labeled as upper bounds. Primary sources include NPS historic records, NASA historic preservation materials, military base public affairs publications, operator press releases, and structural engineering firm project descriptions.

Modern airline and cargo MRO sites can be enormous in aggregate, but we excluded campus totals and multi-building program areas unless a single hangar's clear-span footprint could be isolated.

Know Your Numbers

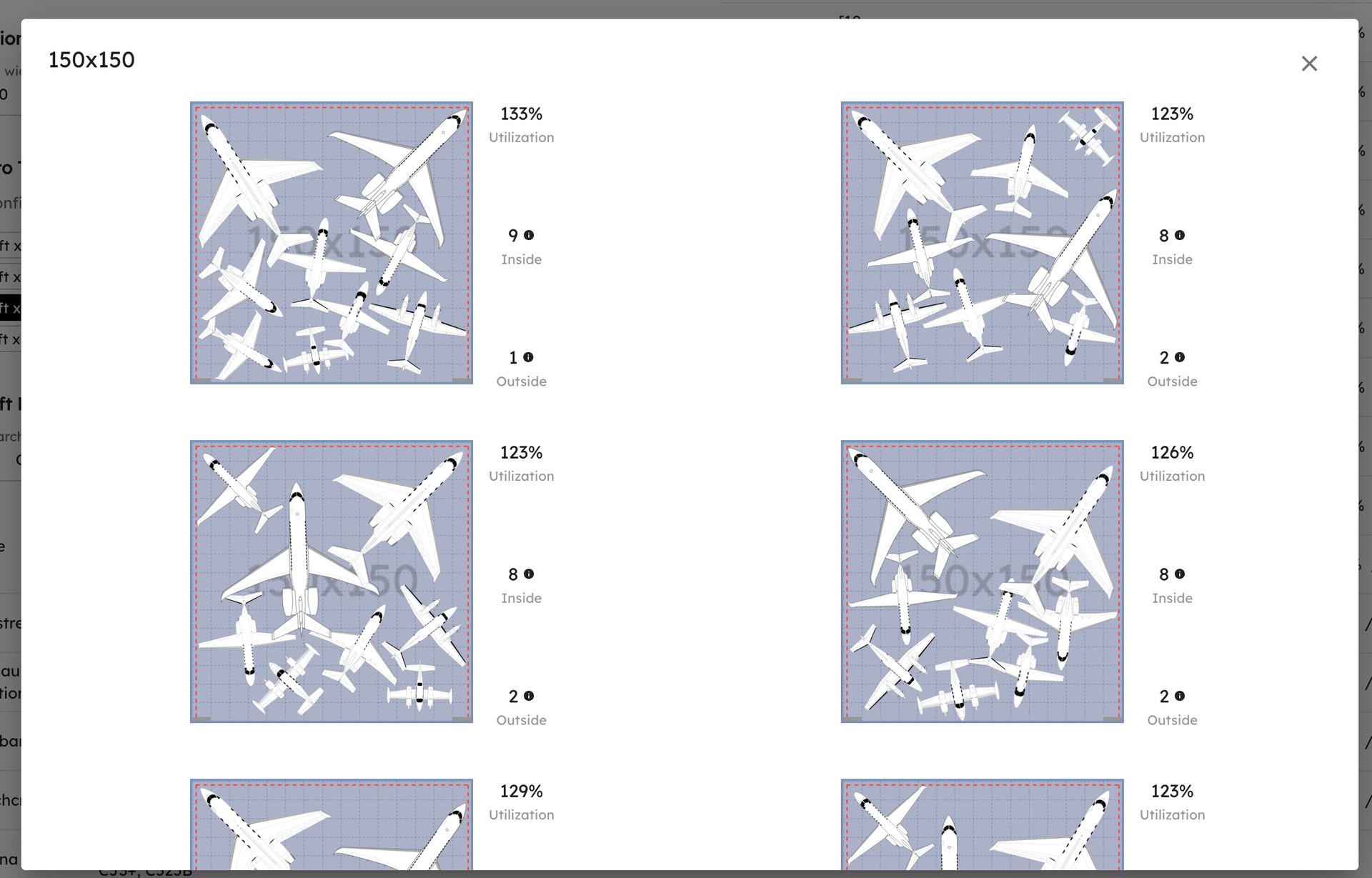

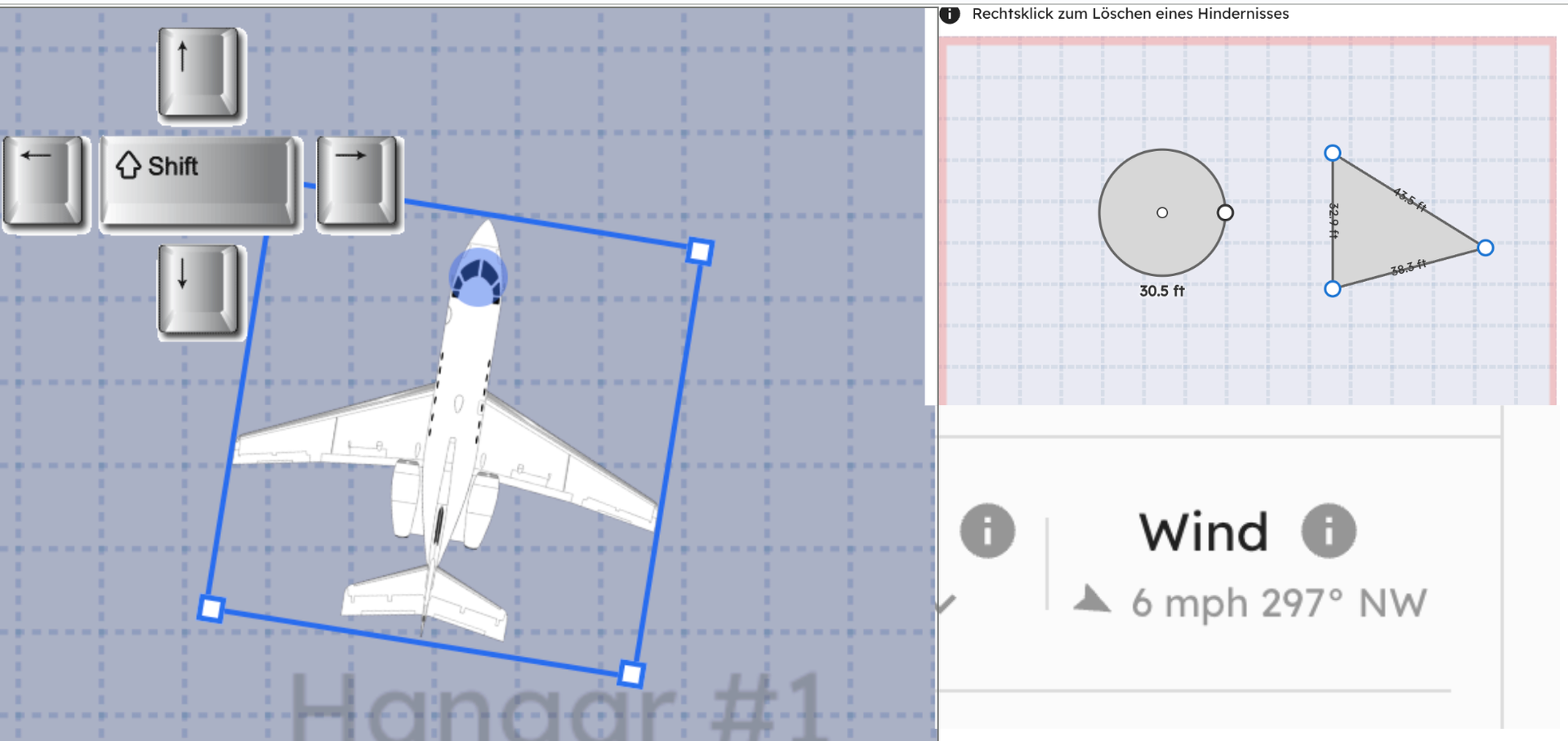

Every hangar on this list was built to solve the same problem you face: how do you fit the most aircraft into a fixed amount of covered space? The tools are different (you probably don't need 600-ton doors), but the math is identical. Clear-span width, door openings, and traffic flow aren't engineering abstractions. They're the variables that decide whether you accommodate that G650 tonight or watch it taxi to the FBO across the field.

If you know your dimensions, AirPlx can model your layout and show you where the unused capacity is. Most operators find 15-25% more positions hiding in the geometry they already have. That's not a building expansion. That's $124,800+ per position you're leaving on the ramp.