FBO Staffing and Training: Addressing High Turnover and Rising Costs

Published on September 9, 2025 • 4 min read

Every FBO manager knows this story: You hire someone promising, spend six weeks training them, invest countless hours of supervision, and then watch them walk out the door right when they're finally useful.

With turnover rates hitting 90% at some operations and training costs pushing $24,000 per employee, FBOs are bleeding money and burning out their remaining staff.

Why This Cycle Keeps Repeating

The aviation industry experiences significant turnover challenges, with rates as high as 50% in ground handling according to IATA's 2023 industry survey. Most FBOs are dealing with serious costs:

What This Actually Costs You

Training a single line tech runs anywhere from $8,000 at smaller operations to $30,000+ at major facilities when you factor in wages, supervision time, and lost productivity while they're learning.

Most techs need 6-12 months to hit full productivity, but here's the kicker—most leave before they get there. Meanwhile, you're dealing with more safety incidents—research shows that 27,000 ramp accidents occur worldwide annually, with high turnover being a contributing factor—and customer complaints from inexperienced staff fumbling VIP services.

The reality is that many operations end up putting poorly trained people on the ramp because they're desperate to fill shifts and keep operations running.

Here's what that looks like in practice: One East Coast FBO hired 12 line techs in January. By December, only 2 were left. The GM did the math and realized they'd burned through $180,000 just on training—before counting recruitment costs, overtime for burned-out existing staff, or customer complaints.

Modern line service requires specialized skills that take months to develop—if techs stay that long

Modern line service requires specialized skills that take months to develop—if techs stay that long

Why Good People Keep Walking Away

Sure, pay matters, but the real problems run deeper:

Training stuck in the past: Today's line techs are juggling complex fuel systems, hazmat protocols, sophisticated ground support equipment, and white-glove customer service. But most FBO training programs haven't changed much since the 1960s—lots of verbal instruction and hoping people figure it out.

The math doesn't add up: When Amazon warehouses are now paying over $22/hour on average for climate-controlled work, it's hard to convince someone to take $16/hour for a job that has them working outside in 100-degree heat or subzero cold.

Nowhere to go: Smart, ambitious people won't stick around if they can't see a path forward. When your best line tech realizes they'll be doing the exact same job in two years, they start looking elsewhere.

Digital tools are transforming how progressive FBOs train and retain their teams

Digital tools are transforming how progressive FBOs train and retain their teams

What's Actually Working for Smart FBOs

The operators who've figured this out aren't doing anything revolutionary—they're just being smarter about the basics.

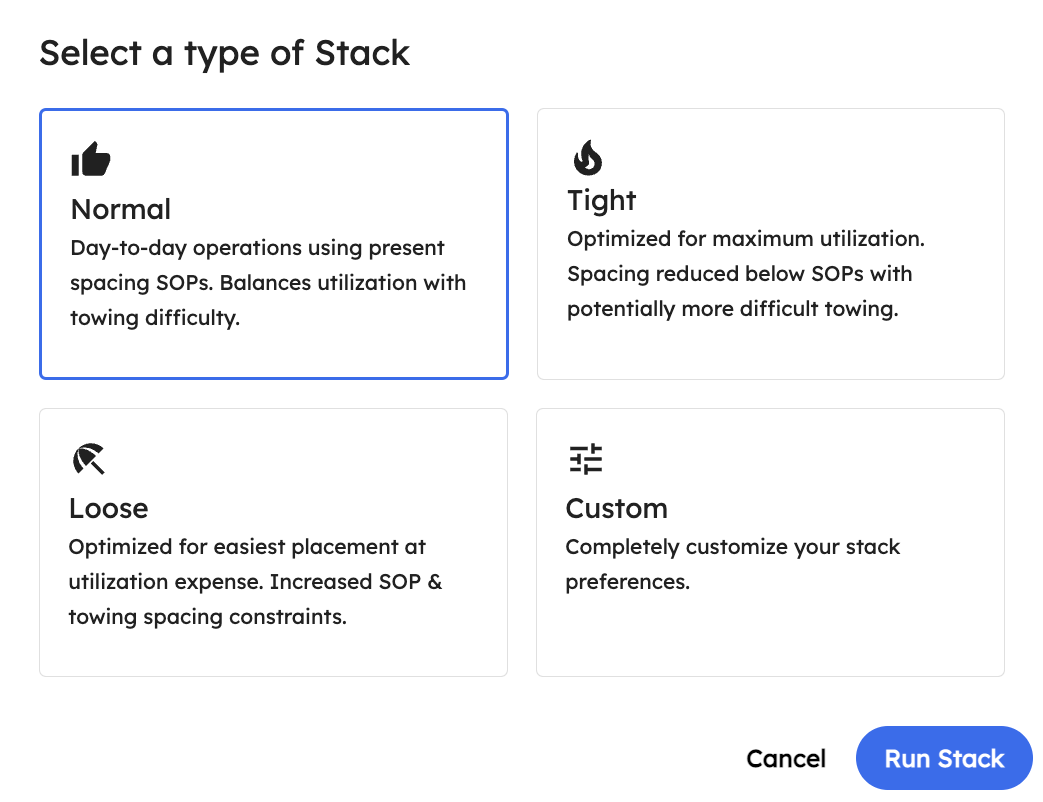

Speed Up Training with Better Tools

Some FBOs are cutting training time by a third using visual systems that show aircraft positioning in 3D rather than making people imagine it. One mid-sized operation in the Southwest tracked their numbers over 18 months and found they went from 8 weeks of training down to 5.5 weeks. That saved them about $5,200 per new hire, and their retention jumped from 35% to 58%.

Show People Where They Can Go

Instead of hiring people into dead-end jobs, map out what growth looks like. Start someone at $15-18/hour as a line tech, show them they can move to $18-22 as a lead within a year, and maybe hit supervisor at $22-26 within 18 months. People stay when they see a future.

FBOs using modern hangar management systems report 35% better employee retention

FBOs using modern hangar management systems report 35% better employee retention

Why Visual Training Actually Works

Most FBO training still relies on verbal explanations and flat diagrams to teach 3D spatial problems. Think about it—you're asking someone to visualize complex aircraft movements in their head based on descriptions like "two spots left of the fuel truck."

The reality is that new techs spend weeks trying to build mental maps of these complex spaces, making mistakes while they figure it out. And when something changes—weather delays shuffle the arrival schedule, or maintenance takes up half the hangar—they're back to square one.

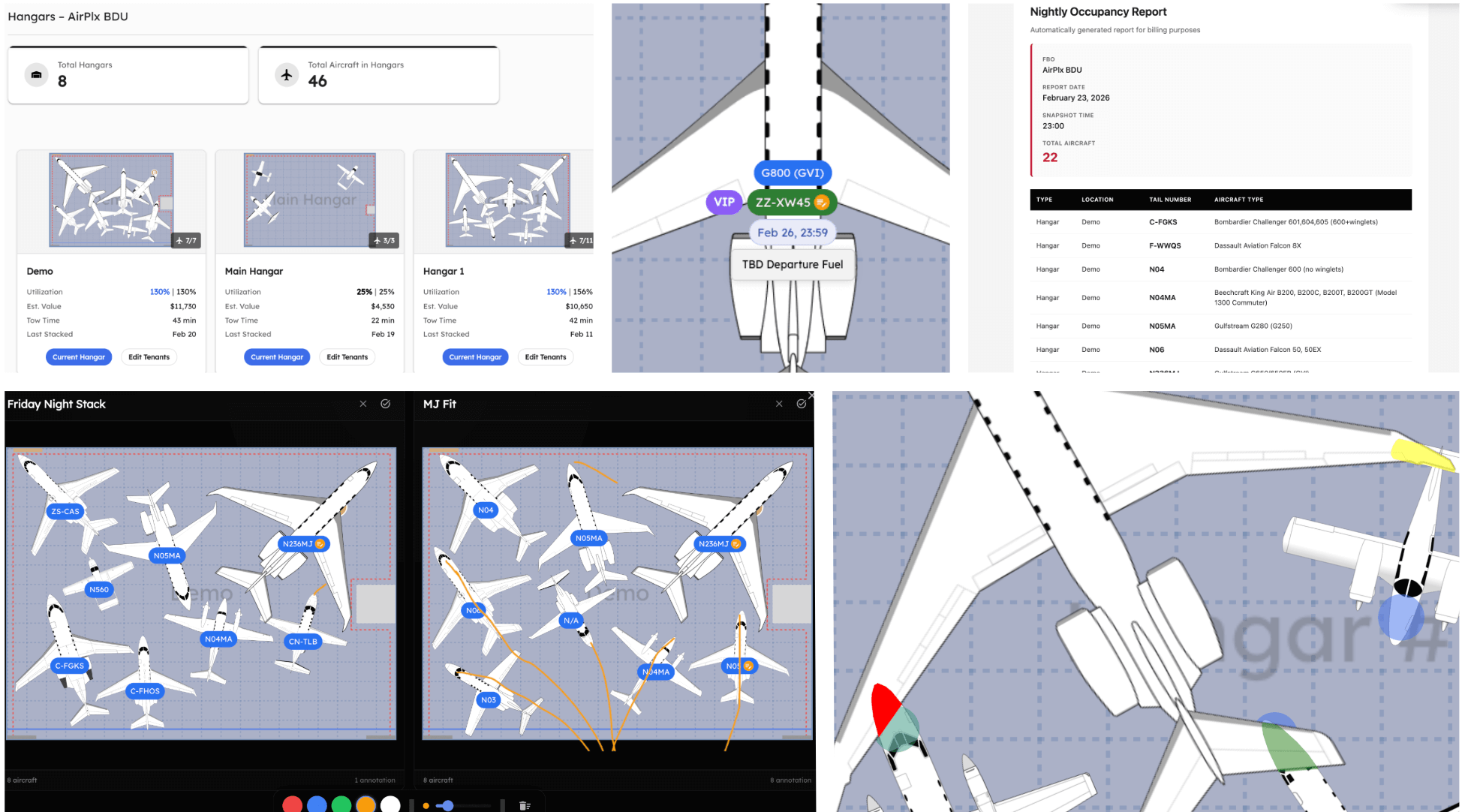

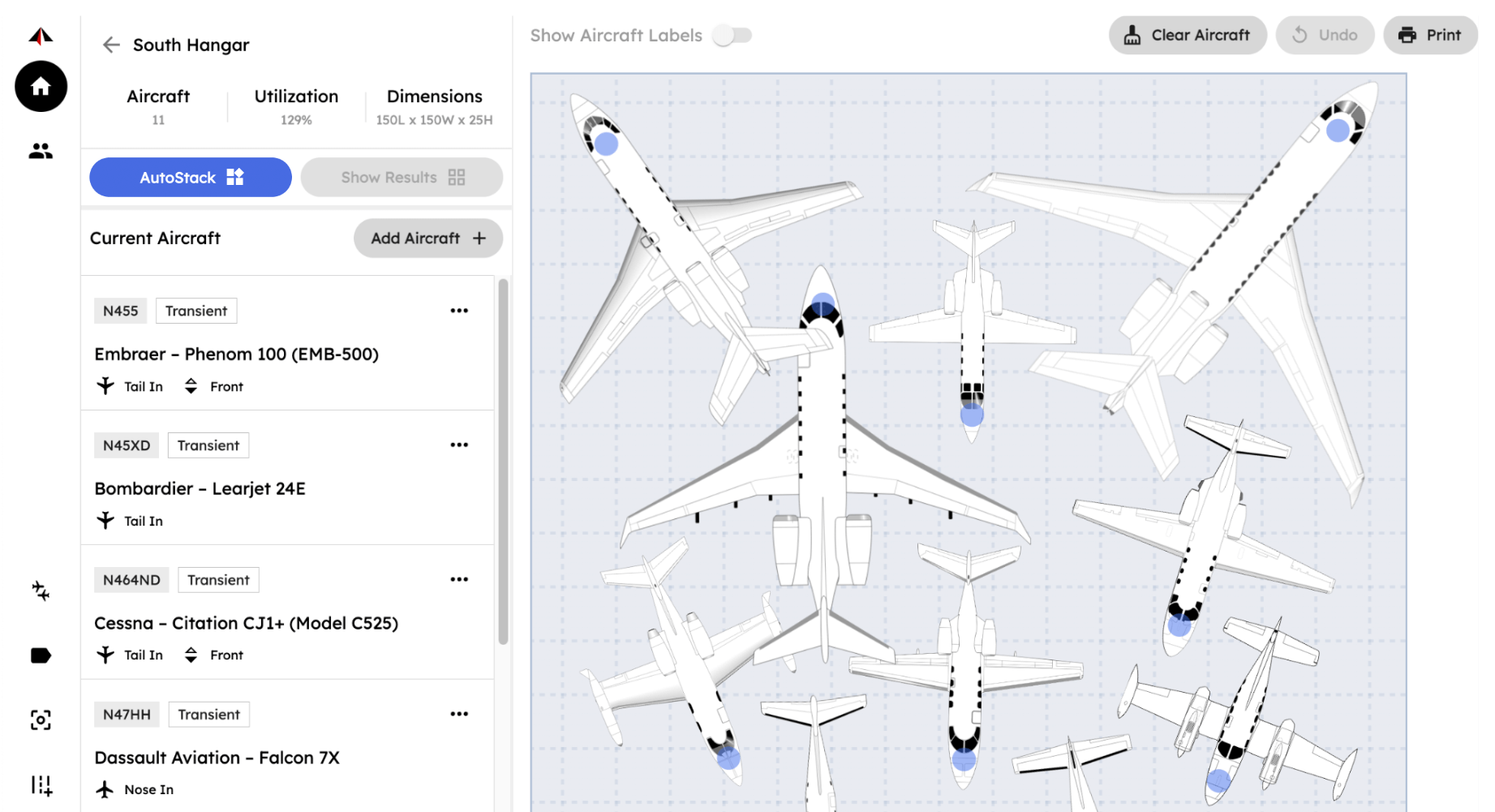

AirPlx takes a different approach. Instead of making people memorize dozens of different scenarios, our visual system shows them exactly where aircraft fit and how to move them safely. It's like having GPS for your hangar instead of trying to navigate by memory. Learn about hangar optimization best practices and 3D stacking strategies that support better training. Calculate your ROI on training improvements.

"Yeah, I Can Stack It—But What About Everyone Else?"

When the FBO calls during your family vacation because nobody else knows how to fit three jets in the hangar

When the FBO calls during your family vacation because nobody else knows how to fit three jets in the hangar

If you've got 20 years at the same hangar, you can probably arrange aircraft in your sleep. The problem isn't you—it's that you're the only one who can do it right.

So when there's a tricky arrival sequence on your day off, guess who gets called? When the new guy is working nights and three jets show up at once, guess who has to walk him through it over the phone?

Our customers aren't using AirPlx because they need help. They're using it so they don't have to be the hangar guru 24/7. It's about taking that expertise you've built over two decades and making it available to your whole team—so you can actually go home.

The Simplicity Factor

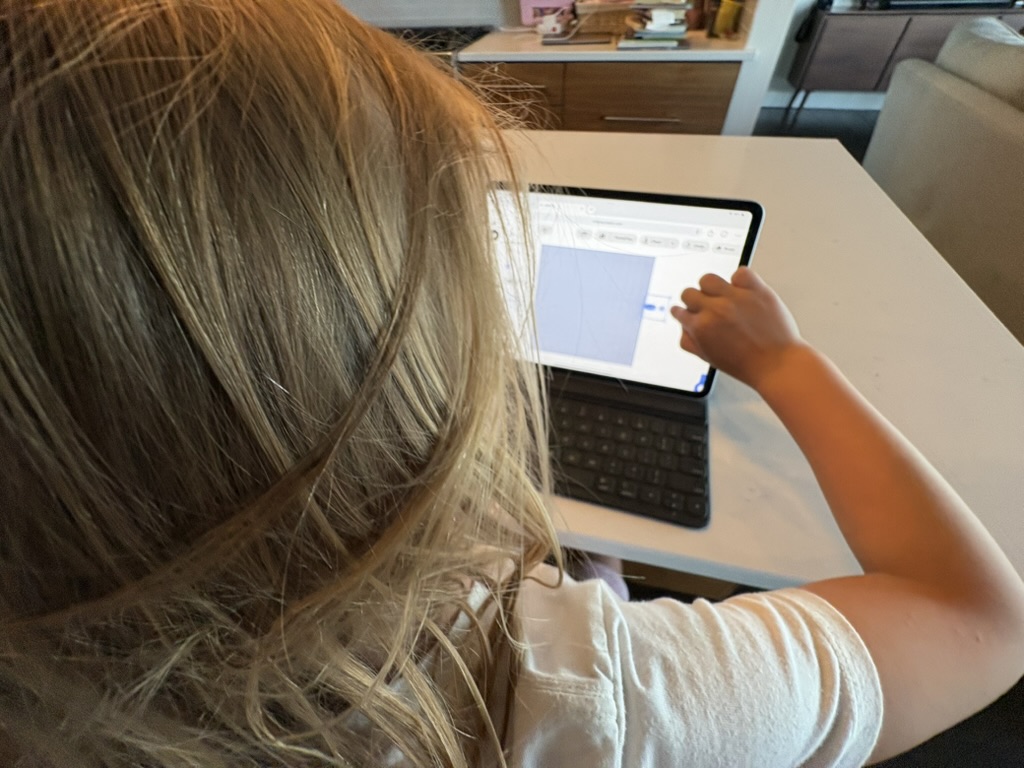

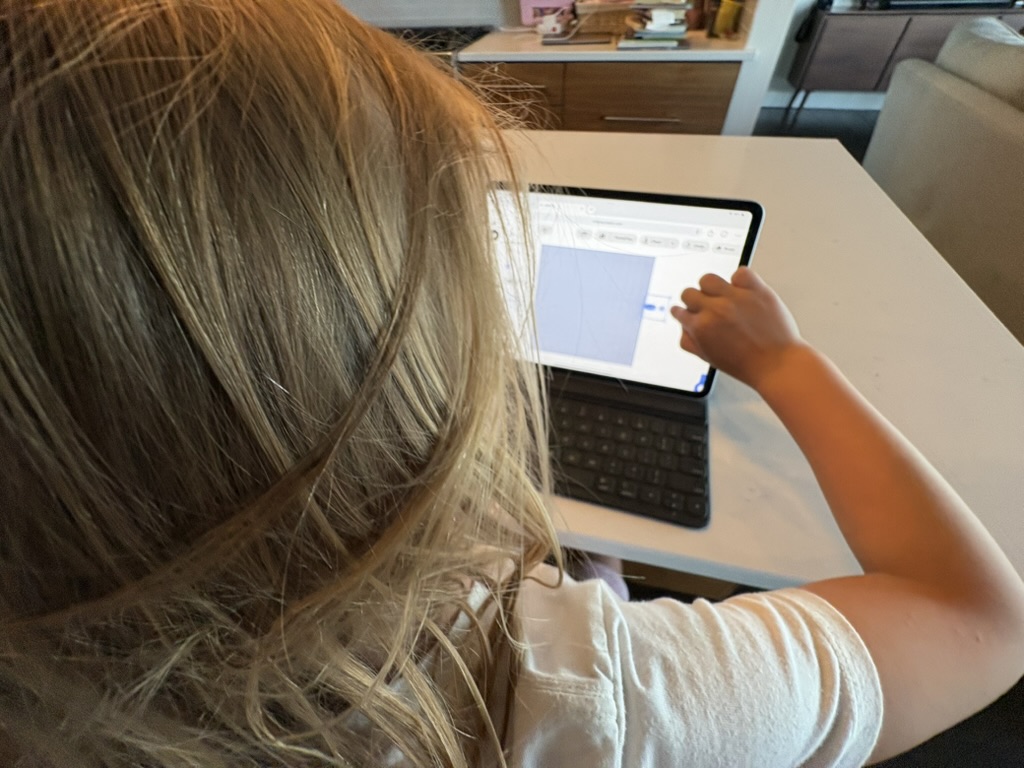

Here's the thing about good design—it shouldn't require a manual. We learned this firsthand when my 5-year-old daughter discovered AirPlx on my iPad. Without any guidance, she figured out how to create aircraft stacks on her own, moving planes around like puzzle pieces until they fit perfectly.

Her review? "It's really good, Dad, but it should be a little more rainbow." 🌈 ✈️

When a 5-year-old can master your hangar management software without help, you know the interface works

When a 5-year-old can master your hangar management software without help, you know the interface works

That's the test we aim for. If complex spatial arrangements make sense to a kindergartner, they'll definitely click with new line techs. It's not about dumbing anything down—it's about removing the mental gymnastics that slow down training and create confusion.

The Bottom Line

If you're running a mid-sized FBO (45-75 aircraft), you're probably losing around $280,000 every year to this problem. The math is pretty straightforward: hire 10 people, spend $22,000 training each one, and watch 70% of them leave within 18 months.

The FBOs that have tackled this are seeing real improvements. Training time drops from 8 weeks to about 5-6 weeks. Training costs go from $22,000 down to $16,000-18,500 per person. And crucially, retention jumps from 30% to somewhere between 45-65%.

The aviation industry will need 1.47 million new professionals by 2034 according to CAE's Aviation Talent Forecast. The operators who figure out how to train people faster and keep them longer are going to have a huge advantage.