Simulated Hangar Stacking to Find the Best Tug

Published on September 1, 2025 • 4 min read

I wanted to answer a simple question: which tugs actually help you fit more aircraft in your hangar?

Instead of just reading spec sheets, I used our software to run a real test. I took a 20,000 sq ft hangar with an actual fleet mix and ran three different tug scenarios through AirPlx to see which one wins.

The results show exactly why your tug choice matters for hangar revenue.

The Setup

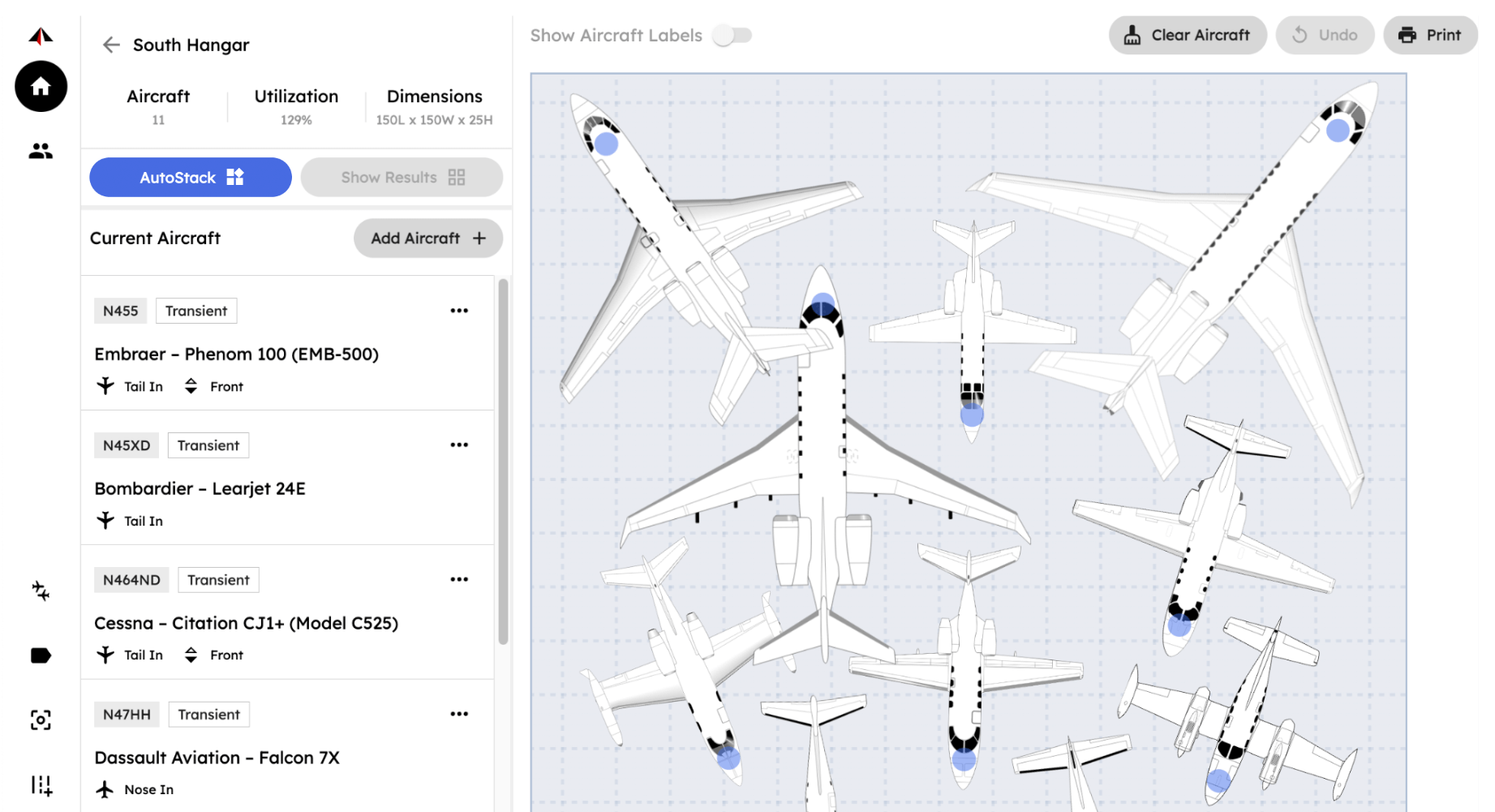

Here's what we're going to do: we're going to use AirPlx's AutoStack to simulate stacking an identical hangar with 3 different tugs. AirPlx accounts for things like turning radii, towbar lengths, garage doors, obstacles, and safety clearances. It's the next best thing to doing it in real-life.

Test Parameters:

- Hangar size: 20,000 sq ft with standard bi-fold doors

- Aircraft mix: Citation VII, Cessna 207 Skywagon, 2 Gulfstream G350s, Challenger 3500, Citation CJ2, SF50 Vision Jet

- Revenue model: $20,000/month at 100% hangar utilization

The Data

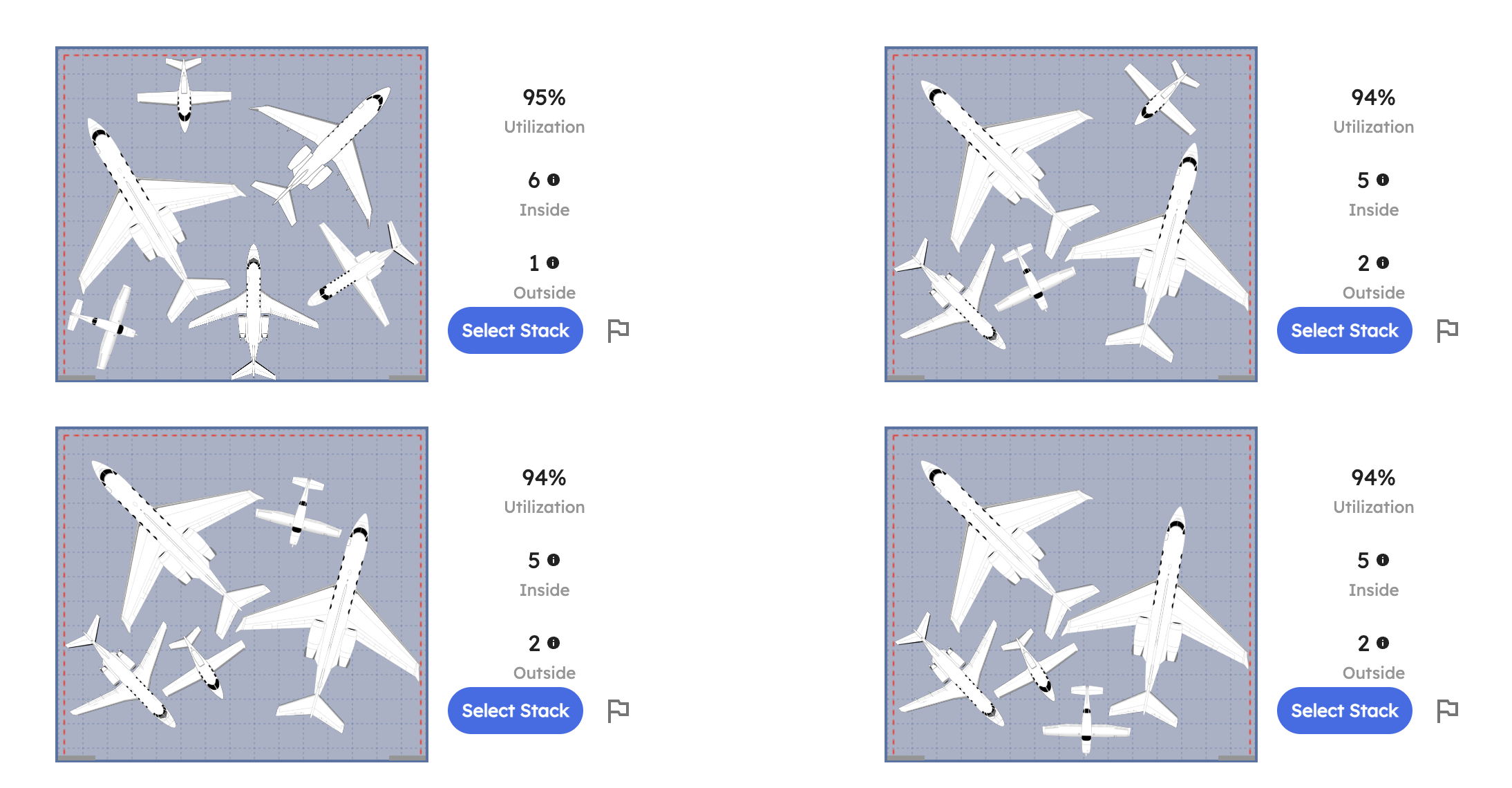

Scenario 1: Diesel Tug + 10ft Towbar

Result: 6 aircraft @ 95% utilization

Pretty funky stack. Wide turning radius forces awkward positioning.

Revenue: $19,000/month (95% × $20k)

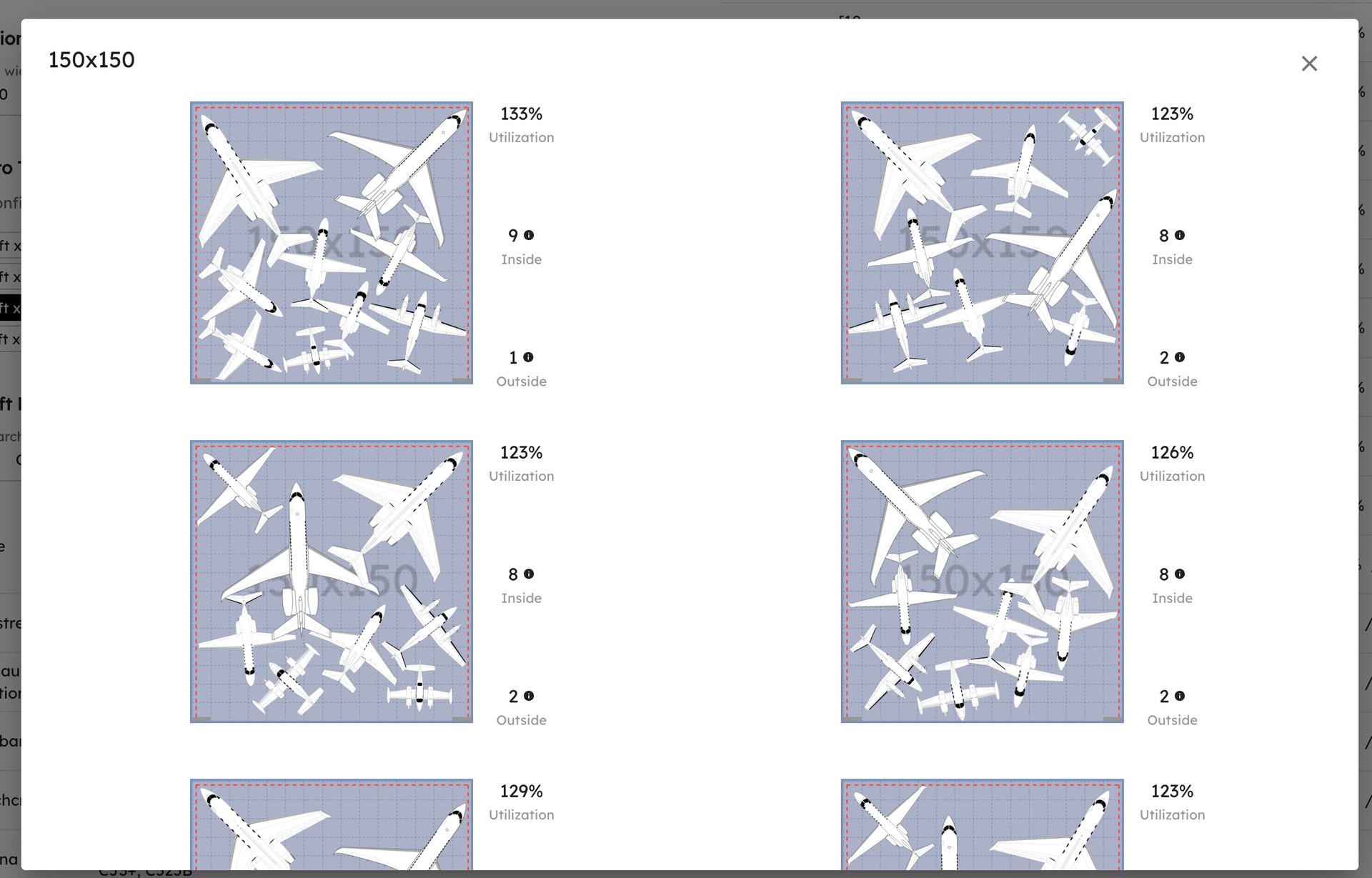

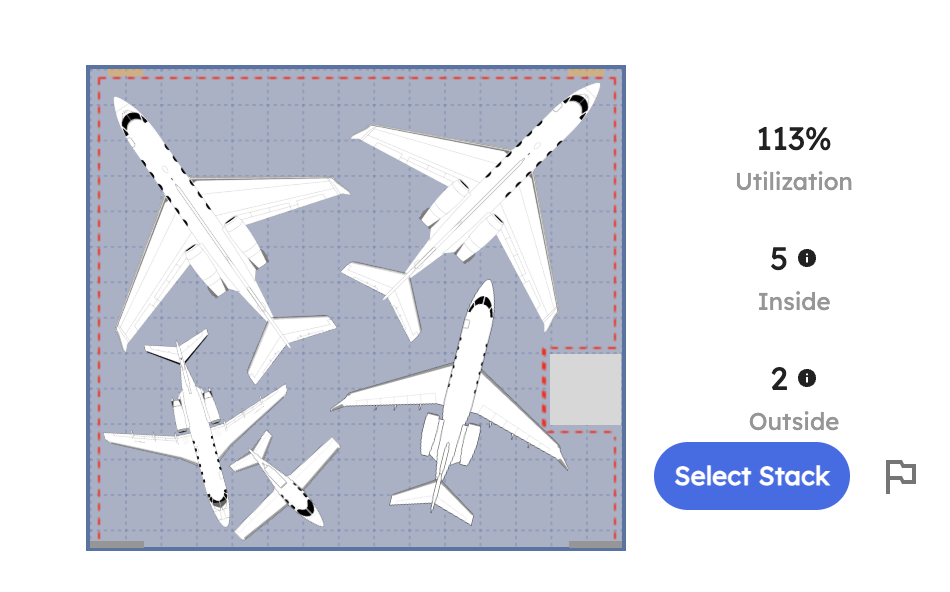

Scenario 2: LEKTRO 88 Towbarless Electric

Result: 5 aircraft @ 113% utilization (+18% improvement)

Way better! Squeeze in another 18%!

Revenue: $22,600/month (113% × $20k = +$3,600 vs diesel)

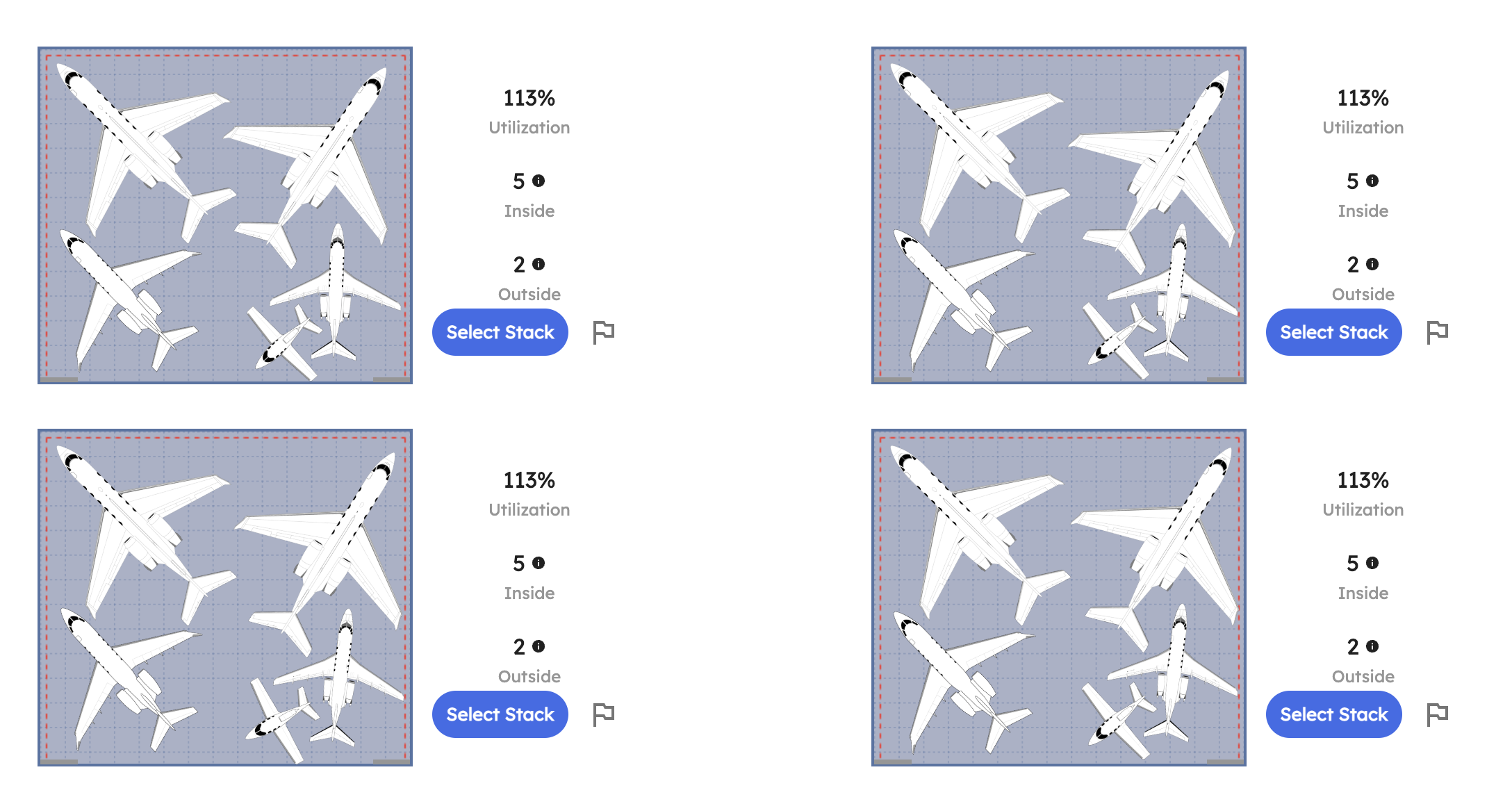

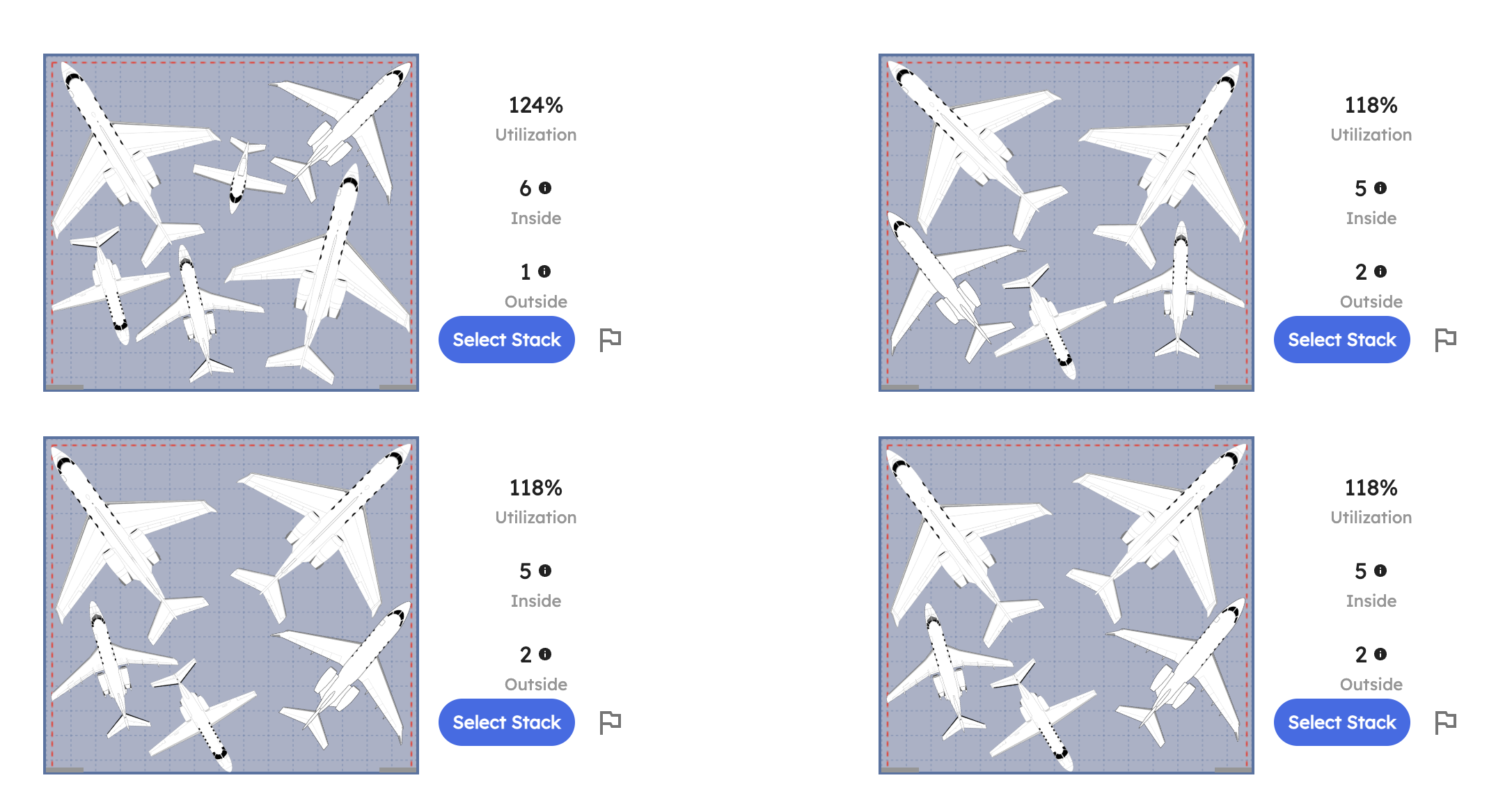

Scenario 3: Remote-Controlled Tug

Result: 6 aircraft @ 125% utilization (+30% vs diesel, +12% vs LEKTRO)

The champion. Surgical precision positioning.

Revenue: $25,000/month (125% × $20k = +$6,000 vs diesel)

The Results: Side-by-Side Comparison

Here's what the experiment revealed:

Tug Performance Summary:

- Diesel + 10ft Bar: 6 aircraft, 95% utilization, $19,000/month

- LEKTRO 88 Electric: 5 aircraft, 113% utilization, $22,600/month (+$3,600)

- Remote Control: 6 aircraft, 125% utilization, $25,000/month (+$6,000)

Key Takeaway: Remote control wins on revenue, but LEKTRO 88 achieves highest efficiency per aircraft. The diesel setup fits the most planes but generates the least revenue per square foot.

Why We Can Generate This Data

AirPlx handles all the edge cases that matter:

- Tug constraints: Turning radii, towbar lengths, operator positioning

- Physical obstacles: Support columns, HVAC units, maintenance equipment

- Door systems: Hangar doors, garage doors, service bay openings

- Aircraft specifics: Wing sweep, tail heights, ground clearances

- Operational realities: Emergency exits, maintenance access, utility locations

Most tools treat aircraft like simple rectangles. AirPlx models the complete operational reality of how different tugs actually work in real hangars with real constraints.

Hot Take: Which Tugs to Buy

For most FBOs: LEKTRO 88 Series ($110,000-130,000)

- Best bang for buck with proven 15% capacity improvements

- Handles 88,000 lbs (covers most business jets)

- Solid service network and reliability

For tight spaces: Mototok remote tugs ($75,000-95,000)

- Ultimate precision positioning

- Perfect for complex layouts or premium positioning needs

- Higher learning curve but maximum flexibility

Budget option: Conventional diesel with shorter towbar ($35,000-50,000)

- Still an improvement over long towbars

- Good stepping stone before going towbarless

Avoid: Anything without a local service network. Downtime kills ROI. You can have your tug fleet dialed in but they're not running, it doesn't matter.

The Closer

AirPlx gives you the data to make smart equipment decisions. Instead of guessing what might work, you can see exactly what will work in your specific hangar with your specific fleet.

Learn more about how hangar stacking software can transform your operations, or book a demo to see what's possible with your hangar.