Know which aircraft fits in which bay—before it arrives

Assign aircraft to maintenance bays using 3D dimensions. See schedule conflicts before they delay work. Get more throughput from existing space.

Trusted by leading MRO facilities

100+

Facilities

800+

Aircraft

1-2 Days

To Go Live

Same Day

Custom Adds

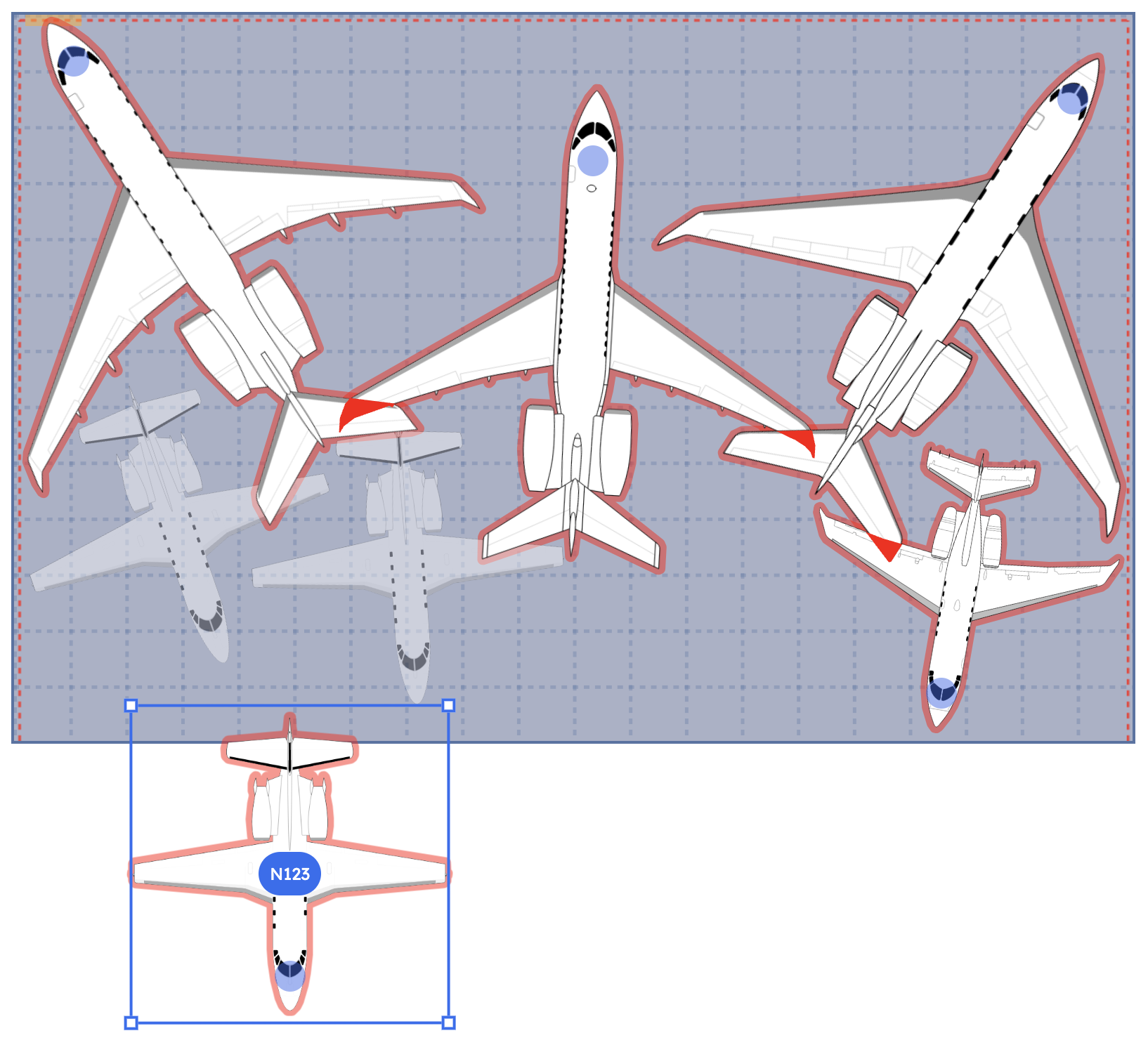

Know if it fits before it arrives

Wingspan, length, height, tail clearance—all checked before assignment. No guessing whether the G650 clears the door.

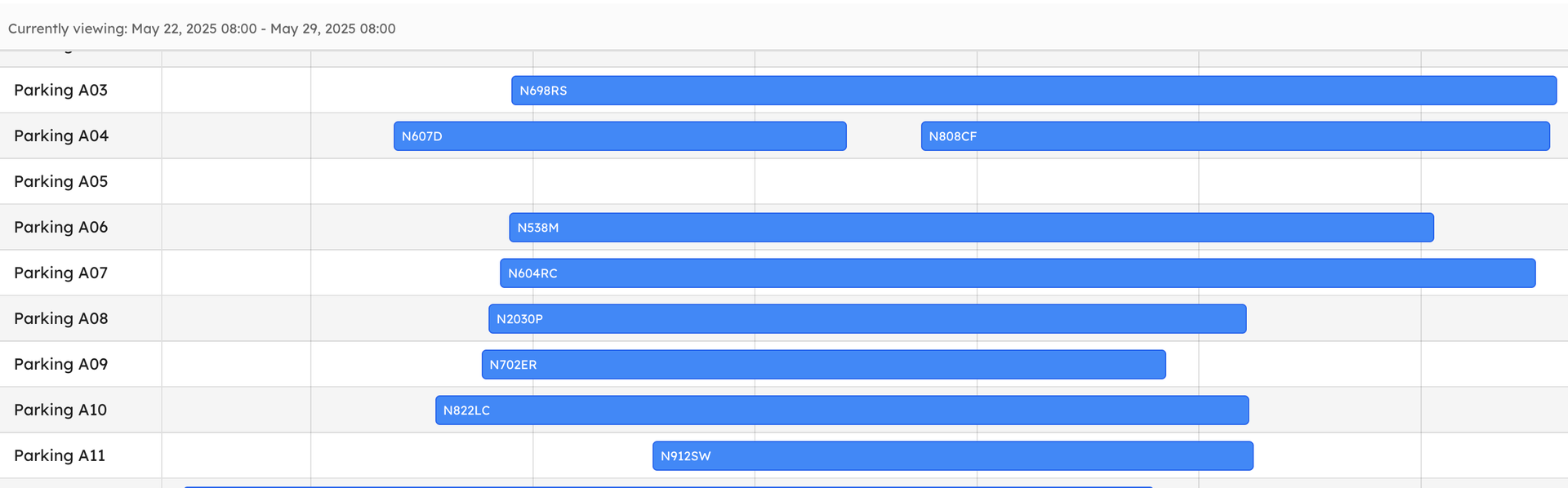

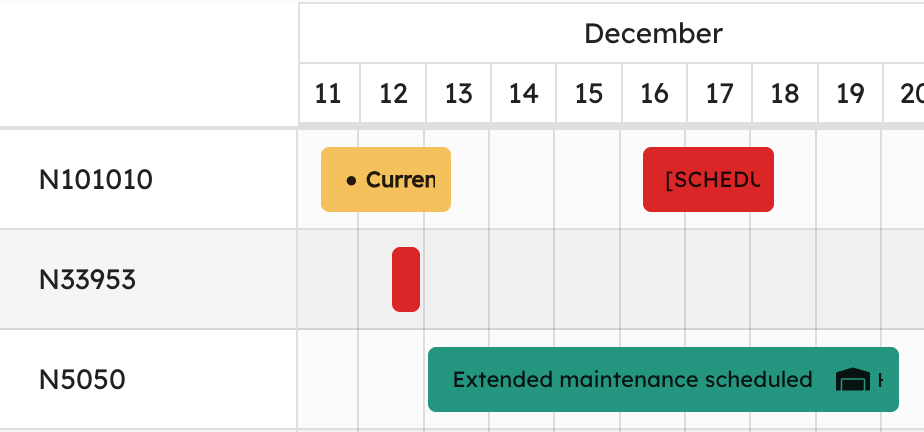

See schedule conflicts before crews arrive

Flags overlapping events across all bays. When schedules slip, you see the conflict immediately—not when crews show up to find no space.

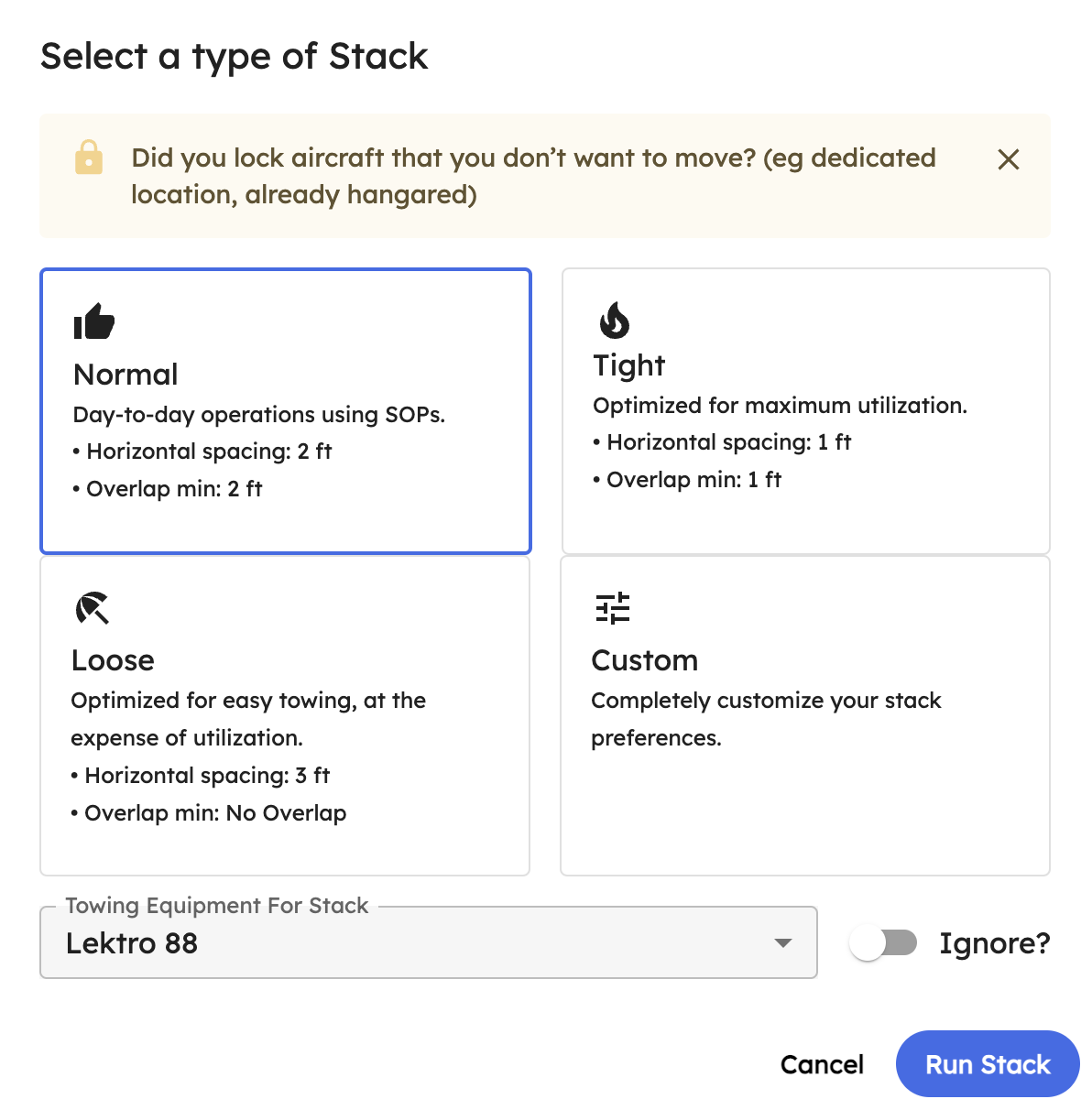

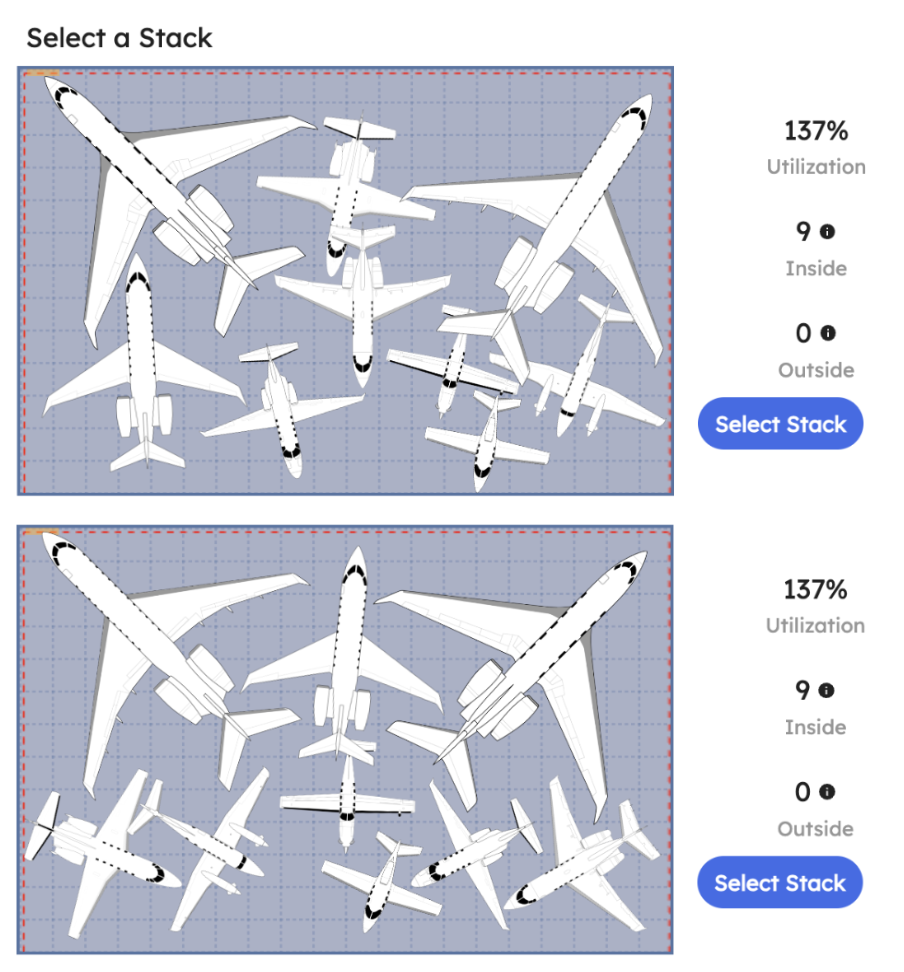

More aircraft through the same space

Optimizes bay assignments across hangars based on aircraft size, job duration, and departure order. Fewer bays sitting empty while aircraft wait outside.

Planners and technicians on the same page

Planners, technicians, leadership—same live schedule. Changes propagate instantly. Fewer calls, fewer surprises.

"A must have tool for any FBO Manager with hangars. Can turn what-if's into reality—plus it's fun!"

Vinny Beyers

FBO General Manager

Atlantic SGJ

Frequently asked questions

Everything you need to know about AirPlx for MROs

How accurate are the 3D aircraft dimensions?

Every aircraft in our database has a 3D model with manufacturer-verified dimensions: wingspan, length, height, tail height, wing height, and ground clearance. This ensures precise fit verification for any bay. For aircraft not in our database, we source dimensions from official specs and add them same-day.

Can AirPlx handle multiple hangars and bays?

Yes. AirPlx supports unlimited hangars and bays within your facility. You can view them individually or together, and our optimization engine considers all available space when suggesting assignments.

How does AirPlx handle maintenance schedule changes?

When schedules shift, AirPlx automatically recalculates conflicts and highlights affected bays. You can drag-and-drop to reassign aircraft, and the system will warn you of any new conflicts before you finalize changes.

What about integrating with our existing MRO software?

AirPlx integrates with popular MRO management systems via API. We can sync aircraft schedules, customer data, and work orders. Contact us for details on specific integrations.

How long does implementation take for an MRO?

Most MRO facilities are fully operational within 1-2 days. We handle hangar setup, bay configurations, and team training. Complex facilities with multiple hangars may take slightly longer.

Can we track maintenance history in AirPlx?

AirPlx focuses on space planning and scheduling rather than detailed maintenance tracking. However, we integrate with MRO management systems that handle work orders, parts, and maintenance history.

See it working on your bays

Most MRO facilities are live in 1–2 days. We configure your bays; you start scheduling.