SmartDraw Alternative for FBO & MRO Hangar Planning

If you're using SmartDraw to plan hangar layouts or schedule maintenance bays, you're using a diagram tool to solve an operational problem.

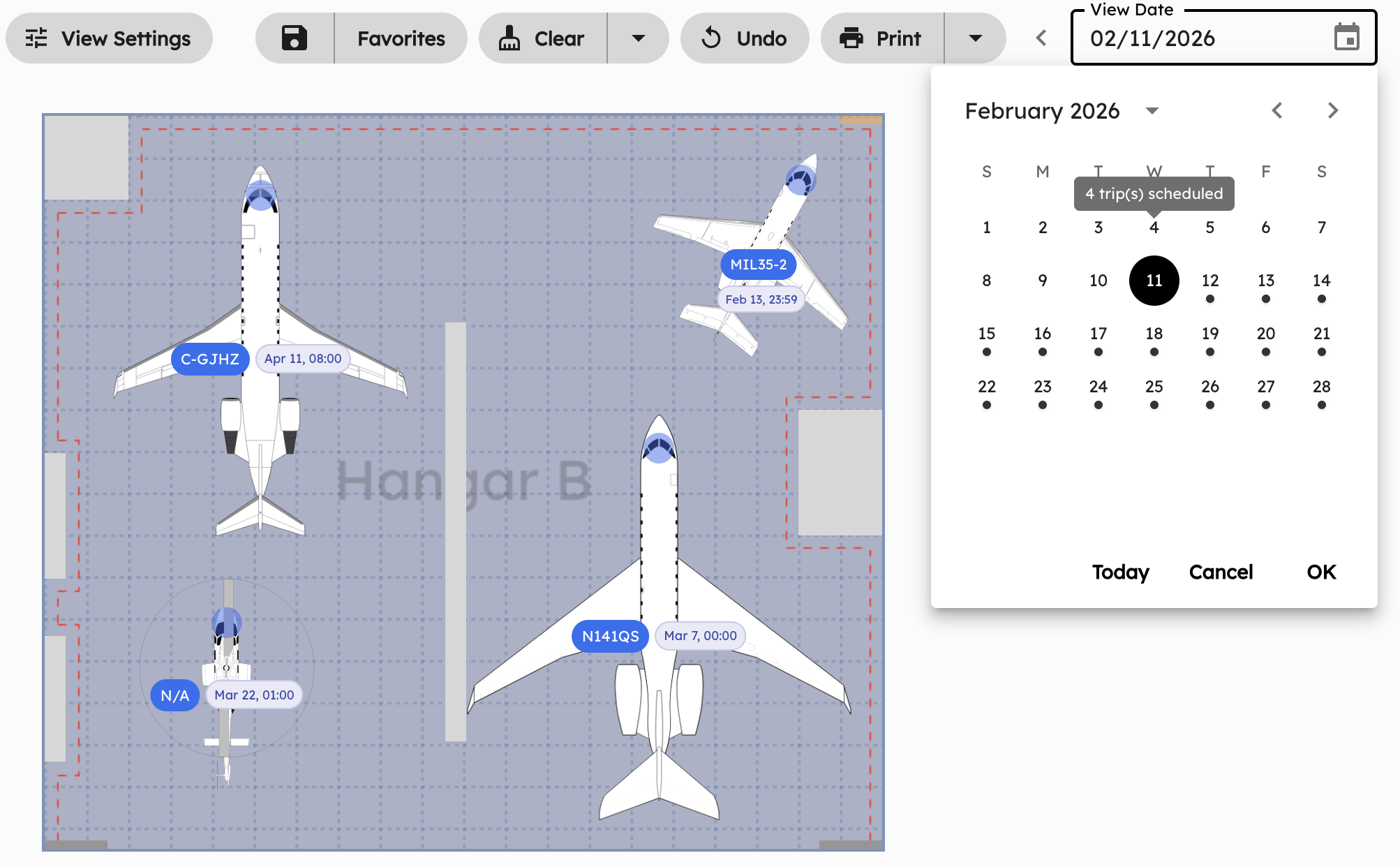

AirPlx replaces static drawings with live hangar optimization, maintenance bay scheduling, AutoParking, and real-time facility visibility — built for FBO ramp operations and MRO bay scheduling.

The Problem with Static Diagram Tools

SmartDraw is excellent for creating diagrams.

But aviation operations are not static.

When ramp traffic spikes, a maintenance schedule slips, or an unplanned arrival forces a reshuffle, static layouts break down. Teams end up redrawing positions manually or relying on tribal knowledge instead of system logic.

For FBOs juggling transient parking and departure stacks, the cost is missed revenue. For MROs running heavy checks, the cost is cascading schedule delays — bay scheduling, jig clearances, and multi-week work orders can't live in a static drawing.

AirPlx was built for live operations, not presentation graphics.

What you get with static tools

Static layouts that break when plans change

Manual aircraft sizing—no built-in dimensions

No stacking or overlap logic

No AutoParking optimization

No bay scheduling or conflict detection

Copy-paste workflows for every change

What you get with AirPlx

800+ aircraft models with to-scale dimensions

Multi-door hangar and bay modeling

AutoParking, stacking, and bay scheduling

Live ramp, hangar, and schedule visibility

Multi-week maintenance scheduling with conflict detection

Real-time collaboration across your team

SmartDraw vs. AirPlx

See how the tools compare, feature by feature.

| Feature | SmartDraw | AirPlx |

|---|---|---|

| Static hangar diagram | ||

| Live aircraft stacking | ||

| Multi-door hangar logic | ||

| AutoParking & bay optimization | ||

| Facility-wide operational visibility | ||

| Live schedule integration | ||

| Multi-week bay scheduling & conflict detection | ||

| Designed for aviation ops | ||

| Bottom Line | SmartDraw helps you draw it. | AirPlx helps you run it. |

800+ Aircraft. To-Scale. Updated Monthly.

SmartDraw doesn't know a Gulfstream from a 737. Every shape is a rectangle you draw yourself.

AirPlx includes 800+ real aircraft models with manufacturer-verified dimensions—wingspan, length, height, tail height, and winglet variants. Whether you're placing a G650 next to a King Air 350 or verifying a 737-800 fits in Bay 3 for a C-check, the system knows the clearances before the tug moves.

To-Scale Dimensions

Every model uses manufacturer-verified specs—wingspan, length, height, tail clearance, and ground clearance. Critical for bay fit verification and scheduling.

Winglet & Variant Support

737-700 vs 737-800 vs 737 MAX? Each variant is modeled separately with accurate dimensions.

Updated Monthly

New aircraft added regularly. Can't find a model? We add it same-day from official specs.

Built for Peak Operations

During peak ramp traffic, heavy maintenance cycles, or facility-wide schedule shifts, diagram tools require manual updates and constant rework. AirPlx handles the complexity automatically.

Door Constraints

Knows which aircraft fit through which doors—no manual measuring.

Aircraft Dimensions

800+ models with wingspan, height, and tail clearance built in.

Stacking & Fit Logic

Calculates stack depth for FBO hangars and verifies aircraft-to-bay fit for MRO facilities — with safe overlap and clearance rules.

Towing Paths

Ensures tug access so departures and bay transitions don't require costly reshuffles.

Overflow Scenarios

Models ramp overflow and staging area constraints when hangars and bays hit capacity.

Schedule Management

Tracks multi-day and multi-week maintenance holds, flags overlapping assignments, and prevents the schedule cascades that kill MRO throughput.

Moving from SmartDraw?

Upload your existing layout and we'll convert it into a live AirPlx workspace.

No starting from scratch

No re-drawing aircraft footprints

No downtime

Most conversions are completed within 24-48 hours.

"We used SmartDraw for years. It worked — until we needed to actually schedule bays and manage live operations. AirPlx gave us the scheduling visibility we never had."

— Facility Operations Manager

Stop Diagramming. Start Operating.

If you're using SmartDraw for hangar layouts or bay scheduling, it may be time to upgrade from diagrams to operational intelligence.